- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

What Really Makes Toyota’s Production System Resilient

- Willy C. Shih

“Just-in-time” only works as part of a comprehensive suite of strategies.

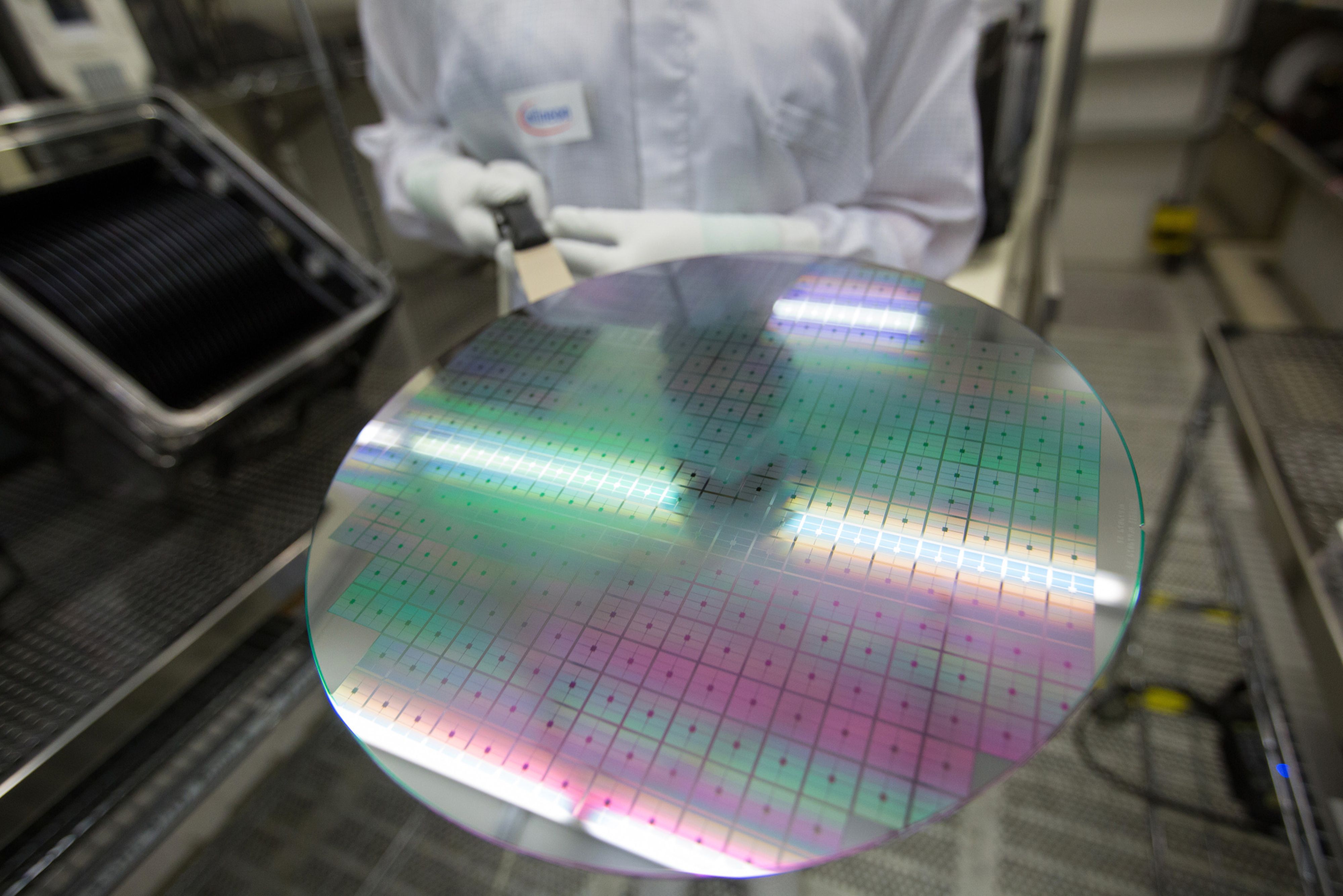

Toyota has fared better than many of its competitors in riding out the supply chain disruptions of recent years. But focusing on how Toyota had stockpiled semiconductors and the problems of other manufacturers, some observers jumped to the conclusion that the era of the vaunted Toyota Production System was over. Not the case, say Toyota executives. TPS is alive and well and is a key reason Toyota has outperformed rivals.

The supply chain disruptions triggered by the Covid-19 pandemic caused major headaches for manufacturers around the world. Nowhere was this felt more acutely than in the auto industry, which faced severe shortages of semiconductor chips and other components. This led many people to argue that just-in-time and lean production methods were dead and being superseded by “just-in-case” stocking of more inventory.

- Willy C. Shih is a Baker Foundation Professor of Management Practice at Harvard Business School.

Partner Center

- About / Contact

- Privacy Policy

- Alphabetical List of Companies

- Business Analysis Topics

Toyota’s Operations Management, 10 Critical Decisions, Productivity

Toyota Motor Corporation’s operations management (OM) covers the 10 decisions for effective and efficient operations. With the global scale of its automobile business and facilities around the world, the company uses a wide set of strategies for the 10 critical decisions of operations management. These strategies account for local and regional automotive market conditions, including the trends examined in the PESTLE analysis (PESTEL analysis) of Toyota . The automaker is an example of successful multinational operations management. These 10 decisions indicate the different areas of the business that require strategic approaches. Toyota also succeeds in emphasizing productivity in all the 10 decisions of operations management.

Toyota’s approaches for the 10 strategic decisions of operations management show the importance of coordinated efforts for ensuring streamlined operations and high productivity in international business. Successful operations management leads to high productivity, which supports competitive advantages over other automakers, such as Ford , General Motors , Tesla , BMW , and Hyundai. Nonetheless, these competitors continuously enhance their operations and create challenges to Toyota’s competitive advantages.

Toyota’s Operations Management, 10 Critical Decision Areas

1. Design of Goods and Services . Toyota addresses this strategic decision area of operations management through technological advancement and quality. The company uses its R&D investments to ensure advanced features in its products. Toyota’s mission statement and vision statement provide a basis for the types and characteristics of these products. Moreover, the automaker accounts for the needs and qualities of dealership personnel in designing after-sales services. Despite its limited influence on dealership employment, Toyota’s policies and guidelines ensure the alignment between dealerships and this area of the company’s operations management.

2. Quality Management . To maximize quality, the company uses its Toyota Production System (TPS). Quality is one of the key factors in TPS. Also, the firm addresses this strategic decision area of operations management through continuous improvement, which is covered in The Toyota Way, a set of management principles. These principles and TPS lead to high-quality processes and outputs, which enable innovation capabilities and other strengths shown in the SWOT analysis of Toyota . In this regard, quality is a critical success factor in the automotive company’s operations.

3. Process and Capacity Design . For this strategic decision area of operations management, Toyota uses lean manufacturing, which is also embodied in TPS. The company emphasizes waste minimization to maximize process efficiency and capacity utilization. Lean manufacturing helps minimize costs and supports business growth, which are objectives of Toyota’s generic strategy for competitive advantage and intensive strategies for growth . Thus, the car manufacturer supports business efficiency and cost-effectiveness in its process and capacity design. Cost-effective processes support the competitive selling prices that the company uses for most of its automobiles.

4. Location Strategy . Toyota uses global, regional, and local location strategies. For example, the company has dealerships and localized manufacturing plants in the United States, China, Thailand, and other countries. The firm also has regional facilities and offices. Toyota’s marketing mix (4Ps) influences the preferred locations for dealerships. The automaker addresses this strategic decision area of operations management through a mixed set of strategies.

5. Layout Design and Strategy . Layout design in Toyota’s manufacturing plants highlights the application of lean manufacturing principles. In this critical decision area, the company’s operations managers aim for maximum efficiency of workflow. On the other hand, dealership layout design satisfies the company’s standards but also includes decisions from dealership personnel.

6. Job Design and Human Resources . The company applies The Toyota Way and TPS for this strategic decision area of operations management. The firm emphasizes respect for all people in The Toyota Way, and this is integrated in HR programs and policies. These programs and policies align with Toyota’s organizational culture (business culture) . Also, the company has training programs based on TPS to ensure lean manufacturing practice. Moreover, Toyota’s company structure (business structure) affects this area of operations management. For example, the types and characteristics of jobs are specific to the organizational division, which can have human resource requirements different from those of other divisions.

7. Supply Chain Management . Toyota applies lean manufacturing for supply chain management. In this strategic decision area of operations management, the company uses automation systems for real-time adjustments in supply chain activity. In this way, the automotive business minimizes the bullwhip effect in its supply chain. It is worth noting that this area of operations management is subject to the bargaining power of suppliers. Even though the Five Forces analysis of Toyota indicates that suppliers have limited power, this power can still affect the automotive company’s productivity and operational effectiveness.

8. Inventory Management . In addressing this strategic decision area of operations management, Toyota minimizes inventory levels through just-in-time inventory management. The aim is to minimize inventory size and its corresponding cost. This inventory management approach is covered in the guidelines of TPS.

9. Scheduling . Toyota follows lean manufacturing principles in its scheduling. The company’s goal for this critical decision area of operations management is to minimize operating costs. Cost-minimization is maintained through HR and resource scheduling that changes according to market conditions.

10. Maintenance . Toyota operates a network of strategically located facilities to support its global business. The company also has a global HR network that supports flexibility and business resilience. In this strategic decision area of operations management, the company uses the global extent of its automotive business reach to ensure optimal and stable productivity. Effective maintenance of assets and business processes optimizes efficiency for Toyota’s sustainability and related CSR and ESG goals .

Productivity at Toyota

Toyota’s operations management uses productivity measures or criteria based on business process, personnel, area of business, and other variables. Some of these productivity measures are as follows:

- Number of product units per time (manufacturing plant productivity)

- Revenues per dealership (dealership productivity)

- Number of batch cycles per time (supply chain productivity)

- Cannas, V. G., Ciano, M. P., Saltalamacchia, M., & Secchi, R. (2023). Artificial intelligence in supply chain and operations management: A multiple case study research. International Journal of Production Research , 1-28.

- Jin, T. (2023). Bridging reliability and operations management for superior system availability: Challenges and opportunities. Frontiers of Engineering Management , 1-15.

- Toyota Motor Corporation – Form 20-F .

- Toyota Motor Corporation – R&D Centers .

- Toyota Production System .

- U.S. Department of Commerce – International Trade Administration – Automotive Industry .

- Copyright by Panmore Institute - All rights reserved.

- This article may not be reproduced, distributed, or mirrored without written permission from Panmore Institute and its author/s.

- Educators, Researchers, and Students: You are permitted to quote or paraphrase parts of this article (not the entire article) for educational or research purposes, as long as the article is properly cited and referenced together with its URL/link.

About Stanford GSB

- The Leadership

- Dean’s Updates

- School News & History

- Commencement

- Business, Government & Society

- Centers & Institutes

- Center for Entrepreneurial Studies

- Center for Social Innovation

- Stanford Seed

About the Experience

- Learning at Stanford GSB

- Experiential Learning

- Guest Speakers

- Entrepreneurship

- Social Innovation

- Communication

- Life at Stanford GSB

- Collaborative Environment

- Activities & Organizations

- Student Services

- Housing Options

- International Students

Full-Time Degree Programs

- Why Stanford MBA

- Academic Experience

- Financial Aid

- Why Stanford MSx

- Research Fellows Program

- See All Programs

Non-Degree & Certificate Programs

- Executive Education

- Stanford Executive Program

- Programs for Organizations

- The Difference

- Online Programs

- Stanford LEAD

- Seed Transformation Program

- Aspire Program

- Seed Spark Program

- Faculty Profiles

- Academic Areas

- Awards & Honors

- Conferences

Faculty Research

- Publications

- Working Papers

- Case Studies

Research Hub

- Research Labs & Initiatives

- Business Library

- Data, Analytics & Research Computing

- Behavioral Lab

Research Labs

- Cities, Housing & Society Lab

- Golub Capital Social Impact Lab

Research Initiatives

- Corporate Governance Research Initiative

- Corporations and Society Initiative

- Policy and Innovation Initiative

- Rapid Decarbonization Initiative

- Stanford Latino Entrepreneurship Initiative

- Value Chain Innovation Initiative

- Venture Capital Initiative

- Career & Success

- Climate & Sustainability

- Corporate Governance

- Culture & Society

- Finance & Investing

- Government & Politics

- Leadership & Management

- Markets and Trade

- Operations & Logistics

- Opportunity & Access

- Technology & AI

- Opinion & Analysis

- Email Newsletter

Welcome, Alumni

- Communities

- Digital Communities & Tools

- Regional Chapters

- Women’s Programs

- Identity Chapters

- Find Your Reunion

- Career Resources

- Job Search Resources

- Career & Life Transitions

- Programs & Webinars

- Career Video Library

- Alumni Education

- Research Resources

- Volunteering

- Alumni News

- Class Notes

- Alumni Voices

- Contact Alumni Relations

- Upcoming Events

Admission Events & Information Sessions

- MBA Program

- MSx Program

- PhD Program

- Alumni Events

- All Other Events

- Operations, Information & Technology

- Organizational Behavior

- Political Economy

- Classical Liberalism

- The Eddie Lunch

- Accounting Summer Camp

- Videos, Code & Data

- California Econometrics Conference

- California Quantitative Marketing PhD Conference

- California School Conference

- China India Insights Conference

- Homo economicus, Evolving

- Political Economics (2023–24)

- Scaling Geologic Storage of CO2 (2023–24)

- A Resilient Pacific: Building Connections, Envisioning Solutions

- Adaptation and Innovation

- Changing Climate

- Civil Society

- Climate Impact Summit

- Climate Science

- Corporate Carbon Disclosures

- Earth’s Seafloor

- Environmental Justice

- Operations and Information Technology

- Organizations

- Sustainability Reporting and Control

- Taking the Pulse of the Planet

- Urban Infrastructure

- Watershed Restoration

- Junior Faculty Workshop on Financial Regulation and Banking

- Ken Singleton Celebration

- Marketing Camp

- Quantitative Marketing PhD Alumni Conference

- Presentations

- Theory and Inference in Accounting Research

- Stanford Closer Look Series

- Quick Guides

- Core Concepts

- Journal Articles

- Glossary of Terms

- Faculty & Staff

- Researchers & Students

- Research Approach

- Charitable Giving

- Financial Health

- Government Services

- Workers & Careers

- Short Course

- Adaptive & Iterative Experimentation

- Incentive Design

- Social Sciences & Behavioral Nudges

- Bandit Experiment Application

- Conferences & Events

- Get Involved

- Reading Materials

- Teaching & Curriculum

- Energy Entrepreneurship

- Faculty & Affiliates

- SOLE Report

- Responsible Supply Chains

- Current Study Usage

- Pre-Registration Information

- Participate in a Study

Toyota: Demand Chain Management

- Priorities for the GSB's Future

- See the Current DEI Report

- Supporting Data

- Research & Insights

- Share Your Thoughts

- Search Fund Primer

- Affiliated Faculty

- Faculty Advisors

- Louis W. Foster Resource Center

- Defining Social Innovation

- Impact Compass

- Global Health Innovation Insights

- Faculty Affiliates

- Student Awards & Certificates

- Changemakers

- Dean Jonathan Levin

- Dean Garth Saloner

- Dean Robert Joss

- Dean Michael Spence

- Dean Robert Jaedicke

- Dean Rene McPherson

- Dean Arjay Miller

- Dean Ernest Arbuckle

- Dean Jacob Hugh Jackson

- Dean Willard Hotchkiss

- Faculty in Memoriam

- Stanford GSB Firsts

- Class of 2024 Candidates

- Certificate & Award Recipients

- Dean’s Remarks

- Keynote Address

- Teaching Approach

- Analysis and Measurement of Impact

- The Corporate Entrepreneur: Startup in a Grown-Up Enterprise

- Data-Driven Impact

- Designing Experiments for Impact

- Digital Business Transformation

- The Founder’s Right Hand

- Marketing for Measurable Change

- Product Management

- Public Policy Lab: Financial Challenges Facing US Cities

- Public Policy Lab: Homelessness in California

- Lab Features

- Curricular Integration

- View From The Top

- Formation of New Ventures

- Managing Growing Enterprises

- Startup Garage

- Explore Beyond the Classroom

- Stanford Venture Studio

- Summer Program

- Workshops & Events

- The Five Lenses of Entrepreneurship

- Leadership Labs

- Executive Challenge

- Arbuckle Leadership Fellows Program

- Selection Process

- Training Schedule

- Time Commitment

- Learning Expectations

- Post-Training Opportunities

- Who Should Apply

- Introductory T-Groups

- Leadership for Society Program

- Certificate

- 2024 Awardees

- 2023 Awardees

- 2022 Awardees

- 2021 Awardees

- 2020 Awardees

- 2019 Awardees

- 2018 Awardees

- Social Management Immersion Fund

- Stanford Impact Founder Fellowships and Prizes

- Stanford Impact Leader Prizes

- Social Entrepreneurship

- Stanford GSB Impact Fund

- Economic Development

- Energy & Environment

- Stanford GSB Residences

- Environmental Leadership

- Stanford GSB Artwork

- A Closer Look

- California & the Bay Area

- Voices of Stanford GSB

- Business & Beneficial Technology

- Business & Sustainability

- Business & Free Markets

- Business, Government, and Society Forum

- Second Year

- Global Experiences

- JD/MBA Joint Degree

- MA Education/MBA Joint Degree

- MD/MBA Dual Degree

- MPP/MBA Joint Degree

- MS Computer Science/MBA Joint Degree

- MS Electrical Engineering/MBA Joint Degree

- MS Environment and Resources (E-IPER)/MBA Joint Degree

- Academic Calendar

- Clubs & Activities

- LGBTQ+ Students

- Military Veterans

- Minorities & People of Color

- Partners & Families

- Students with Disabilities

- Student Support

- Residential Life

- Student Voices

- MBA Alumni Voices

- A Week in the Life

- Career Support

- Employment Outcomes

- Cost of Attendance

- Knight-Hennessy Scholars Program

- Yellow Ribbon Program

- BOLD Fellows Fund

- Application Process

- Loan Forgiveness

- Contact the Financial Aid Office

- Evaluation Criteria

- GMAT & GRE

- English Language Proficiency

- Personal Information, Activities & Awards

- Professional Experience

- Letters of Recommendation

- Optional Short Answer Questions

- Application Fee

- Reapplication

- Deferred Enrollment

- Joint & Dual Degrees

- Entering Class Profile

- Event Schedule

- Ambassadors

- New & Noteworthy

- Ask a Question

- See Why Stanford MSx

- Is MSx Right for You?

- MSx Stories

- Leadership Development

- How You Will Learn

- Admission Events

- Personal Information

- GMAT, GRE & EA

- English Proficiency Tests

- Career Change

- Career Advancement

- Daycare, Schools & Camps

- U.S. Citizens and Permanent Residents

- Requirements

- Requirements: Behavioral

- Requirements: Quantitative

- Requirements: Macro

- Requirements: Micro

- Annual Evaluations

- Field Examination

- Research Activities

- Research Papers

- Dissertation

- Oral Examination

- Current Students

- Education & CV

- International Applicants

- Statement of Purpose

- Reapplicants

- Application Fee Waiver

- Deadline & Decisions

- Job Market Candidates

- Academic Placements

- Stay in Touch

- Faculty Mentors

- Current Fellows

- Standard Track

- Fellowship & Benefits

- Group Enrollment

- Program Formats

- Developing a Program

- Diversity & Inclusion

- Strategic Transformation

- Program Experience

- Contact Client Services

- Campus Experience

- Live Online Experience

- Silicon Valley & Bay Area

- Digital Credentials

- Faculty Spotlights

- Participant Spotlights

- Eligibility

- International Participants

- Stanford Ignite

- Frequently Asked Questions

- Founding Donors

- Location Information

- Participant Profile

- Network Membership

- Program Impact

- Collaborators

- Entrepreneur Profiles

- Company Spotlights

- Seed Transformation Network

- Responsibilities

- Current Coaches

- How to Apply

- Meet the Consultants

- Meet the Interns

- Intern Profiles

- Collaborate

- Research Library

- News & Insights

- Program Contacts

- Databases & Datasets

- Research Guides

- Consultations

- Research Workshops

- Career Research

- Research Data Services

- Course Reserves

- Course Research Guides

- Material Loan Periods

- Fines & Other Charges

- Document Delivery

- Interlibrary Loan

- Equipment Checkout

- Print & Scan

- MBA & MSx Students

- PhD Students

- Other Stanford Students

- Faculty Assistants

- Research Assistants

- Stanford GSB Alumni

- Telling Our Story

- Staff Directory

- Site Registration

- Alumni Directory

- Alumni Email

- Privacy Settings & My Profile

- Success Stories

- The Story of Circles

- Support Women’s Circles

- Stanford Women on Boards Initiative

- Alumnae Spotlights

- Insights & Research

- Industry & Professional

- Entrepreneurial Commitment Group

- Recent Alumni

- Half-Century Club

- Fall Reunions

- Spring Reunions

- MBA 25th Reunion

- Half-Century Club Reunion

- Faculty Lectures

- Ernest C. Arbuckle Award

- Alison Elliott Exceptional Achievement Award

- ENCORE Award

- Excellence in Leadership Award

- John W. Gardner Volunteer Leadership Award

- Robert K. Jaedicke Faculty Award

- Jack McDonald Military Service Appreciation Award

- Jerry I. Porras Latino Leadership Award

- Tapestry Award

- Student & Alumni Events

- Executive Recruiters

- Interviewing

- Land the Perfect Job with LinkedIn

- Negotiating

- Elevator Pitch

- Email Best Practices

- Resumes & Cover Letters

- Self-Assessment

- Whitney Birdwell Ball

- Margaret Brooks

- Bryn Panee Burkhart

- Margaret Chan

- Ricki Frankel

- Peter Gandolfo

- Cindy W. Greig

- Natalie Guillen

- Carly Janson

- Sloan Klein

- Sherri Appel Lassila

- Stuart Meyer

- Tanisha Parrish

- Virginia Roberson

- Philippe Taieb

- Michael Takagawa

- Terra Winston

- Johanna Wise

- Debbie Wolter

- Rebecca Zucker

- Complimentary Coaching

- Changing Careers

- Work-Life Integration

- Career Breaks

- Flexible Work

- Encore Careers

- Join a Board

- D&B Hoovers

- Data Axle (ReferenceUSA)

- EBSCO Business Source

- Global Newsstream

- Market Share Reporter

- ProQuest One Business

- Student Clubs

- Entrepreneurial Students

- Stanford GSB Trust

- Alumni Community

- How to Volunteer

- Springboard Sessions

- Consulting Projects

- 2020 – 2029

- 2010 – 2019

- 2000 – 2009

- 1990 – 1999

- 1980 – 1989

- 1970 – 1979

- 1960 – 1969

- 1950 – 1959

- 1940 – 1949

- Service Areas

- ACT History

- ACT Awards Celebration

- ACT Governance Structure

- Building Leadership for ACT

- Individual Leadership Positions

- Leadership Role Overview

- Purpose of the ACT Management Board

- Contact ACT

- Business & Nonprofit Communities

- Reunion Volunteers

- Ways to Give

- Fiscal Year Report

- Business School Fund Leadership Council

- Planned Giving Options

- Planned Giving Benefits

- Planned Gifts and Reunions

- Legacy Partners

- Giving News & Stories

- Giving Deadlines

- Development Staff

- Submit Class Notes

- Class Secretaries

- Board of Directors

- Health Care

- Sustainability

- Class Takeaways

- All Else Equal: Making Better Decisions

- If/Then: Business, Leadership, Society

- Grit & Growth

- Think Fast, Talk Smart

- Spring 2022

- Spring 2021

- Autumn 2020

- Summer 2020

- Winter 2020

- In the Media

- For Journalists

- DCI Fellows

- Other Auditors

- Academic Calendar & Deadlines

- Course Materials

- Entrepreneurial Resources

- Campus Drive Grove

- Campus Drive Lawn

- CEMEX Auditorium

- King Community Court

- Seawell Family Boardroom

- Stanford GSB Bowl

- Stanford Investors Common

- Town Square

- Vidalakis Courtyard

- Vidalakis Dining Hall

- Catering Services

- Policies & Guidelines

- Reservations

- Contact Faculty Recruiting

- Lecturer Positions

- Postdoctoral Positions

- Accommodations

- CMC-Managed Interviews

- Recruiter-Managed Interviews

- Virtual Interviews

- Campus & Virtual

- Search for Candidates

- Think Globally

- Recruiting Calendar

- Recruiting Policies

- Full-Time Employment

- Summer Employment

- Entrepreneurial Summer Program

- Global Management Immersion Experience

- Social-Purpose Summer Internships

- Process Overview

- Project Types

- Client Eligibility Criteria

- Client Screening

- ACT Leadership

- Social Innovation & Nonprofit Management Resources

- Develop Your Organization’s Talent

- Centers & Initiatives

- Student Fellowships

- How Toyota's Just-In-Time (JIT) System Revolutionized Manufacturing

When one thinks of groundbreaking innovations in manufacturing, Toyota's Just-In-Time (JIT) system undoubtedly stands out. Born out of necessity and refined through careful observation and relentless pursuit of efficiency, the JIT system has not only transformed Toyota's operations but has also left an indelible mark on the global manufacturing landscape. Let's delve into this game-changing philosophy.

1. The Birth of JIT

Post-World War II Japan was resource-scarce. With limited space for inventory and a pressing need for diversified automobile production, Toyota faced a challenge. Traditional mass production methods, epitomized by companies like Ford, weren't feasible. Thus, under the guidance of Taiichi Ohno, the company began to develop a system where parts were produced only when needed and in the exact quantities required.

2. JIT Defined

At its essence, JIT is about producing the right item, in the right amount, at the right time. This system minimizes waste by drastically reducing inventory and streamlining production processes.

3. Pillars of JIT

- Kanban System: Serving as the linchpin of JIT, the Kanban system uses cards (or other signaling methods) to indicate when a particular component should be produced or supplied. As products move through the production line, Kanban signals ensure that parts are replenished only when consumed.

- Takt Time: This refers to the maximum amount of time allowed to produce a product to meet customer demand. It helps synchronize production processes, ensuring a smooth, efficient flow.

- Leveling: By spreading production evenly and minimizing fluctuations, Toyota can efficiently allocate resources, reducing downtime and bottlenecks.

4. The Benefits Realized

Toyota's adoption of JIT led to various benefits:

- Reduced Inventory Costs: Large inventories tie up capital and occupy space. By minimizing inventory, Toyota significantly cut storage and handling costs.

- Improved Quality: With a focus on real-time production, defects were detected and addressed promptly, enhancing product quality.

- Flexibility: JIT allowed Toyota to adapt swiftly to changes in market demand, offering a diverse range of models without maintaining vast inventories of each.

5. The Global Ripple Effect

Toyota's success didn't remain a Japanese secret for long. As companies worldwide noted Toyota's efficiency and profitability, they sought to understand the magic behind the scenes. The JIT system, with its undeniable benefits, became a sought-after model:

- Manufacturing: Beyond automobiles, sectors like electronics, aerospace, and consumer goods started to adopt JIT principles, aiming to optimize their processes and reduce waste.

- Supply Chain Management: The JIT philosophy redefined supply chain dynamics, emphasizing partnerships, real-time communication, and synchronized deliveries.

- Lean Manufacturing: JIT principles became foundational to the broader "Lean" philosophy, emphasizing waste reduction and value optimization throughout the production process.

6. Challenges Along the Way

JIT, while transformative, isn't without its challenges. It demands precise coordination, real-time communication, and a high degree of trust among all stakeholders. Any disruption, whether from supplier delays, natural disasters, or geopolitical issues, can have significant repercussions.

7. The Legacy of JIT in the Digital Age

With advancements in technology, particularly the Internet of Things (IoT), Artificial Intelligence (AI), and advanced analytics, the JIT system is evolving. Real-time data, predictive analytics, and smart factories are enhancing JIT's principles, offering even more refined levels of efficiency and responsiveness.

Toyota's Just-In-Time system is a testament to the power of innovation born from necessity. It's a story of how keen observation, a deep understanding of processes, and the courage to challenge conventional wisdom can lead to revolutionary outcomes. In the annals of manufacturing history, JIT stands as a beacon, illuminating the path to efficiency, responsiveness, and quality.

Related Posts

- First American President of Toyota Motor Manufacturing - Given that the Toyota Way is to make decisions slowly, thoroughly considering alternatives (see Make Decisions Slowly by Consensus,Thoroughly Considering All Options; Implement Rapidly (Nemawashi) on nemawashi), it was not...

- Creating the Manufacturing System That Changed the World - In the 1950s, Ohno returned to the place he understood best, the shop floor, and went to work to change the rules of the game. He did not have a...

- The Essence of Toyota Management System - Table of Contents The History and Evolution of TMS The Core Principles of TMS Practices & Techniques Modern Adaptations of TMS The Future of TMS In the world of management,...

- Key Principles of Toyota Production System (TPS) - The Toyota Production System (TPS) is a renowned philosophy that has transformed the manufacturing industry. It's not just a method or a process but a culture, one that prioritizes efficiency,...

- Using the Toyota Way to Transform Technical and Service Organizations - Applying the Toyota Production System outside the shop floor can be done, but this takes some creativity. Certainly, the basic principles can be applied to administrative processes. We sent some...

- The Toyota Way Is More than Tools and Techniques - So you set up your kanban system. (Kanban is the Japanese word for “card,” “ticket,” or “sign” and is a tool for managing the flow and production of materials in...

- Using the Toyota Way for Long-Term Success - Critics often describe Toyota as a “boring company.” This is the kind of boring I like. Top quality year in and year out. Steadily growing sales. Consistent profitability. Huge cash...

- The 14 Principles of the Toyota Way - The Toyota Way, a management philosophy that has propelled Toyota to its current position as a global leader in efficiency and quality, is underpinned by 14 key principles. These principles...

- The Origins of the Toyota Management System - The Toyota Management System (TMS), often interchangeably referred to as the Toyota Production System (TPS), is an iconic example of innovation and operational efficiency. Its impact resonates beyond the automobile...

- Understanding the Toyota Way - For many organizations, the pursuit of efficiency, productivity, and quality has always been paramount. Yet, only a few have managed to achieve a reputation quite like Toyota, the Japanese automotive...

- Toyota's Global Expansion: Strategies and Challenges

- Toyota's Approach to Quality Management: Tools and Techniques

- Toyota's Cross-cultural Communication Strategies in Global Operations

- Toyota's Supplier Relationship Management: Building Long-Term Partnerships

- Toyota Logistics Operation

- Toyota's Joint Ventures and Strategic Alliances

- Toyota's Six Sigma Approach and Its Implementation

- Toyota's Digital Transformation in Manufacturing

- Training and Development: Toyota's Investment in its Employees

Why Toyota’s Just-in-Time Method Is Critical to Its Success

Toyota began using the Just-in-Time method in 1938. However, the true potential of this strategy was realized when it integrated this strategy with TPS.

May 30 2016, Updated 11:08 a.m. ET

Toyota’s Just-in-Time method

The automotive industry is highly capital-intensive in nature. This is the driving reason behind efforts by automakers (XLY) to employ cost-effective business strategies to minimize their costs. The Toyota Production System (or TPS) is one of the most notable business strategies utilized by the automaker.

The Just-in-Time (or JIT) method is an integral part of this strategy. In this part of the series, we’ll explore how Toyota’s (TM) Just-in-Time method evolved and helps the company to minimize its costs.

Evolution of the Toyota Production System

After World War II, the majority of Japanese companies, including automakers, were facing challenges and struggling to survive. At the time, a sharp decline in auto demand and the high costs of production haunted automakers, including Toyota.

Toyota began using the Just-in-Time method in 1938. However, the true potential of this strategy was realized when it integrated this strategy with TPS. The company notes that this system was based on the concept of “the complete elimination of all waste.”

According to the company, “The TPS has evolved through many years of trial and error to improve efficiency based on the Just-in-Time concept developed by Kiichiro Toyoda, the founder of Toyota.” Additionally, a former Toyota vice president, Taiichi Ohno, is also associated with TPS. Ohno helped Toyota in creating the basic framework for the JIT method.

The company describes JIT as “making only what is needed, when it is needed, and in the amount needed.”

How does it work?

Using JIT, Toyota produces its vehicles based on the orders it receives through its dealers. In this production process, the company uses its supply chain in such a manner that only the parts that are needed to manufacture vehicles are received on time. Thus, the manufacturing and transportation of parts take place simultaneously. This allows Toyota to minimize its inventory of vehicle parts.

JIT also emphasizes the importance of work efficiency. According to Toyota’s website, the “use of JIT within the Toyota Production System means that individual cars can be built to order and that every component has to fit perfectly first time because there are no alternatives available.”

Notably, TPS has become very popular globally. It is also used by companies such as Hewlett-Packard (HPQ) , Motorola (MSI) , and General Electric (GE) .

Now, let’s take a look at Toyota’s marketing strategy.

Latest HP Inc News and Updates

- ABOUT Market Realist

- Privacy Policy

- Terms of Use

- CONNECT with Market Realist

- Link to Facebook

- Link to Instagram

- Contact us by Email

Opt-out of personalized ads

© Copyright 2024 Market Realist. Market Realist is a registered trademark. All Rights Reserved. People may receive compensation for some links to products and services on this website. Offers may be subject to change without notice.

THE ESSENCE OF JUST-IN-TIME: PRACTICE-IN-USE AT TOYOTA PRODUCTION SYSTEM MANAGED ORGANIZATIONS - How Toyota Turns Workers Into Problem Solvers

by Sarah Jane Johnston, HBS Working Knowledge

.jpg?height=100&t=1718943257&width=150)

IMAGES

VIDEO

COMMENTS

Just- in - time (JIT) inventory management is the procuring of materials immediately as they. are required for use in pr oduction and doing away with a large inventory. A more specific definition ...

Save. Summary. Toyota has fared better than many of its competitors in riding out the supply chain disruptions of recent years. But focusing on how Toyota had stockpiled semiconductors and the ...

Inventory Management. In addressing this strategic decision area of operations management, Toyota minimizes inventory levels through just-in-time inventory management. ... M. P., Saltalamacchia, M., & Secchi, R. (2023). Artificial intelligence in supply chain and operations management: A multiple case study research. International Journal of ...

system of Toyota and its essential strategy of Just-in-Time. In plain words, Just-in-Time is basically an inventory strategy deployed by. e, allow. ng it to increase its efficiency in the productionprocess. By doing so, i. allows the. ompany to receive goods only in hour of actualrequirement. This further lo.

Abstract. This case study examines Toyota's strategic inventory management. The company has been known for its zero-stock inventory, learning from the lessons of the March 11 tsunami disaster in ...

The Toyota demand chain is efficient, flexible, customer oriented and product specific. The case studies how Toyota uses its advanced distribution channels, inventory management, planning methodologies and production capabilities to create and manage its demand chain, with a particular focus on the Japanese and the North American markets.

The result, of course, was what came to be known as "just-in-time" inventory management, as championed by firms such as Toyota. The approach worked. The amount of inventory needed to support a given sales level shrank. Logistics as a component of the total cost (transport plus inventory) of doing business came down.

Toyota's Just-In-Time system is a testament to the power of innovation born from necessity. It's a story of how keen observation, a deep understanding of processes, and the courage to challenge conventional wisdom can lead to revolutionary outcomes. In the annals of manufacturing history, JIT stands as a beacon, illuminating the path to ...

Toyota achieve "zero inventory", ... Industry —— A Case Study of Toyota. ... This is the first study in supply chain management and logistics (SCMLs) to use the native category approach. ...

Toyota's use of the Andon system is a prime example of Lean Manufacturing in action. This visual management tool allows workers to signal a problem or stop production if an issue arises.

numerical study, we demonstrate that applied Toyota methodology policy is sufficiently accurate and close to optimal. Keywords: average inventory; Inventory management; Toyota Production System TPS, KANBAN INTRODUCTION There is a real problem facing by bearing industry in deciding how to distribute buffer space to reach or maintain throughput, yet

management philosophy, an integrated approach to optimize the use of a company's resources, namely, capital, ... excess inventory and that Toyota would strive to work in partnership with suppliers to level production. Under Ohno's ... Just in Time and Kanban: Case Study of Toyota Production System (TPS) Volume.08, Jan-Dec-2019, Pages: 498 ...

The Toyota Production System (or TPS) is one of the most notable business strategies utilized by the automaker. The Just-in-Time (or JIT) method is an integral part of this strategy.

11/26/2001 Toyota cars and trucks have a reputation for quality—and the company works hard to keep the bar set high. But its methods are not secret. So why can't other carmakers copy Toyota's success? HBS professor Steven Spear says that answer is partially in how the company teaches problem solving to every employee. Toyota's "Rules-in-Use" allow the organization to engage in self-r...

Toyota Inventory Management - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses Toyota's inventory management system including Just-in-Time (JIT) and Lean Manufacturing. It describes how Toyota developed the JIT concept to produce only what is needed when it is needed through continuous flow ...

With less inventory in a system the "rocks" are quickly exposed in production that are disrupting flow. Most companies shy away problems and use inventory to hide these problem and avoid potential disruptions. In Toyota however the opposite logic is applied. By reducing inventory you expose the real problems in a production process quickly

Rising Covid cases have forced key auto suppliers STMicroelectronics NV and Infineon Technologies AG to close facilities, worsening a shortage of chips that's been hammering automakers for months. Bloomberg's supply chain analysis data show Toyota sources from both of those companies. Striking a Balance.

An empirical study on growth of supply chain. management in Toyota Motors. Surabhi Sugathan. Assistant Professor, Dep artment of management, Metas Adventust College, Surat, India. Abstract: The ...

Japanese Management - case study (1) - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document analyzes and evaluates the characteristics of Japanese management using Toyota Motor as a case study. It finds that Toyota has very high managerial efficiency compared to other automakers, due partly to influences of Japanese business culture like consensus decision ...

2.1. Lean theories and description. Lean theories encompass a set of principles and practices aimed at maximizing value while minimizing waste in various processes, originally developed within the context of manufacturing but now applied across industries (Uusitalo & Lavikka, Citation 2021).At its core, lean thinking seeks to deliver more value to customers with fewer resources, thereby ...

4 Institute for the Study of War and AEI's Critical Threats Project 2024 We do not report in detail on Russian war crimes because these activities are well-covered in Western media and do not directly affect the military operations we are assessing and forecasting. We will continue to evaluate and report on the effects of

CDK's dealer management system, or DMS, lets car vendors operate their business, including handling payroll, inventory, customer relations and office operations.

Elektrostal Geography. Geographic Information regarding City of Elektrostal. Elektrostal Geographical coordinates. Latitude: 55.8, Longitude: 38.45. 55° 48′ 0″ North, 38° 27′ 0″ East. Elektrostal Area. 4,951 hectares. 49.51 km² (19.12 sq mi) Elektrostal Altitude.

State Housing Inspectorate of the Moscow Region Elektrostal postal code 144009. See Google profile, Hours, Phone, Website and more for this business. 2.0 Cybo Score. Review on Cybo.

Akio Toyoda ran Toyota for 14 years before handing the reins to a new C.E.O. last year, but some have grown concerned about the control he still wields. By River Akira Davis Reporting from Tokyo ...

In 1954, Elemash began to produce fuel assemblies, including for the first nuclear power plant in the world, located in Obninsk. In 1959, the facility produced the fuel for the Soviet Union's first icebreaker. Its fuel assembly production became serial in 1965 and automated in 1982. 1. Today, Elemash is one of the largest TVEL nuclear fuel ...