Brought to you by:

Apple Inc.: Global Supply Chain Management

By: P. Fraser Johnson

This case focuses on the supply chain strategy of Apple Inc. (Apple). Set in early 2020, it provides a detailed description of the company's supply chain network and capabilities. Data in the case…

- Length: 20 page(s)

- Publication Date: Jun 1, 2020

- Discipline: Operations Management

- Product #: W20472-PDF-ENG

What's included:

- Teaching Note

- Educator Copy

$4.95 per student

degree granting course

$8.95 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

This case focuses on the supply chain strategy of Apple Inc. (Apple). Set in early 2020, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to develop an understanding of Apple's source of competitiveness and to gain insights into the management of a large, complex global supply chain network that focused on the intersection of services, hardware and software. Students will obtain an understanding of the supply chain challenges faced by Apple, in the context of supporting its corporate strategy and growth objectives.

Learning Objectives

This case can be used in an undergraduate- and graduate-level courses on operations management, supply chain management, logistics, business strategy, or marketing. It provides an opportunity to appreciate the complexities of managing a complex global supply chain. After completing the case, students will be able to do the following: Assess Apple's supply chain, and identify its key competitive advantages. Quantify Apple's ability to generate value from its supply chain. Identify potential opportunities and challenges for Apple in improving its supply chain. Analyze the effects of the opportunities and challenges Apple faces in its growth and evolution.

Jun 1, 2020 (Revised: Nov 13, 2023)

Discipline:

Operations Management

Geographies:

United States

Industries:

Ivey Publishing

W20472-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

How Apple Is Organized for Innovation

- Joel M. Podolny

- Morten T. Hansen

When Steve Jobs returned to Apple, in 1997, it had a conventional structure for a company of its size and scope. It was divided into business units, each with its own P&L responsibilities. Believing that conventional management had stifled innovation, Jobs laid off the general managers of all the business units (in a single day), put the entire company under one P&L, and combined the disparate functional departments of the business units into one functional organization. Although such a structure is common for small entrepreneurial firms, Apple—remarkably—retains it today, even though the company is nearly 40 times as large in terms of revenue and far more complex than it was in 1997. In this article the authors discuss the innovation benefits and leadership challenges of Apple’s distinctive and ever-evolving organizational model in the belief that it may be useful for other companies competing in rapidly changing environments.

It’s about experts leading experts.

Idea in Brief

The challenge.

Major companies competing in many industries struggle to stay abreast of rapidly changing technologies.

One Major Cause

They are typically organized into business units, each with its own set of functions. Thus the key decision makers—the unit leaders—lack a deep understanding of all the domains that answer to them.

The Apple Model

The company is organized around functions, and expertise aligns with decision rights. Leaders are cross-functionally collaborative and deeply knowledgeable about details.

Apple is well-known for its innovations in hardware, software, and services. Thanks to them, it grew from some 8,000 employees and $7 billion in revenue in 1997, the year Steve Jobs returned, to 137,000 employees and $260 billion in revenue in 2019. Much less well-known are the organizational design and the associated leadership model that have played a crucial role in the company’s innovation success.

- Joel M. Podolny is the dean and vice president of Apple University in Cupertino, California. The former dean of the Yale School of Management, Podolny was a professor at Harvard Business School and the Stanford Graduate School of Business.

- MH Morten T. Hansen is a professor at the University of California, Berkeley, and a faculty member at Apple University, Apple. He is the author of Great at Work and Collaboration and coauthor of Great by Choice . He was named one of the top management thinkers in the world by the Thinkers50 in 2019. MortentHansen

Partner Center

General Topics

Supply Demand Product Planner Apple Interview

Hello Blinders, I have upcoming interviews with the apple supply demand planner team and was wondering if I could hear people’s perspective on the process, culture and trajectory in this team. Also, they mentioned a case study as part of the process? Any insight on this would be greatly appreciated. Thanks for the help! TC:110k YOE: 3yrs

How are you getting an SDM call at a FAANG with 3 YoE?

Or does SDM not mean Software Development Manager in this context.

Recruiter mentioned SDM as acronym. This is for Apple operations/ Supply chain rather than software development.

Supply Demand Management

This is probably the least sexy/one of the more boring roles within Apple’s operations division. Unlike Global Supply Managers you aren’t involved in contract negotiations with suppliers, aren’t traveling to supplier sites etc. You will instead primarily build long Term Mass Production Schedule forecasts which are only used as a reference point on what to track against. What role are you in at GS? I’d say it’s akin to a back office role at GS

Im in IB, but want a better WLB. Recruiter mentioned a 170k TC which is on par with analyst year 2/3 pay.

Do you know what the hours look like?

I have worked in the Supply Demand Team. I would say work is good, lot of Analytics. I would not call it boring/back office. SDM actually provides the Forecast for GSM/Ops to execute. Management/Team is good, good culture and WLB compared to a lot of other Operations Teams at Apple.

Hi, can you share your experience? A recruiter reached to me and asked to apply.

At what stage are you?

Scheduled phone call with the recruiter. Background info on me- I’m in DC, do FP&A for a GSE. Left MS last year. 3 YOE. TC: ~140 Looking for info on comp, type of work, exit ops etc.

Hi! Can you share your experience with the case study?

Do you work at Apple?

Hi! I’m currently interviewing for this role and have the THA scheduled this weekend and an interview next Monday - can anyone please share how your experience was, what to expect and any tips/tricks? TIA!

hi, what about your interview, can you share some tips and the presentation case study

This is a really crappy team- low pay, very manual redundant ops work, toxic people. Run away!! Hope you are not in already.

Currently in the second round of interviews with the case. Any tips on preparation or insight you can provide?

Hi, can you share about the case study, what should I prepare. Thanks

Tech Industry

Bf is forcing

🚗 Tesla Layoff Email

Personal Finance

I regret maxing out my 401k

Cool part about getting laid off

Today I Learned

TIL: Protesting on a Bridge = Bad 🚫

Get Active in Our Amazing Community of Over 450,000 Peers!

Does anyone know what to expect for an apple "worldwide supply demand planner" technical interview.

I have an upcoming interview for a WorldWide Supply Demand Chain Planner position at Apple that requires a technical portion of the interview, as well as a full case study later on.

Can someone familiar with the role describe the day to day and what to expect in terms of technical parts of the supply demand interview?

Overview of answers

- Date ascending

- Date descending

Feel free to contact me, then we can have a call on this topic :)

Related Cases

Bain/BCG - Hunger Warriors

Bcg - us supply chain crisis.

Bain Final Round: Pharmacy Delivery Entry

Similar questions, dhl management consulting, market size of parcel delivery in your city, case study question.

- Select category

- General Feedback

- Case Interview Preparation

- Technical Problems

Award winner: Apple Inc: Global Supply Chain Management

This case won the Production and Operations Management category at The Case Centre Awards and Competitions 2022 . #CaseAwards2022

View the video of the award presentation on 27 May 2022 .

Author perspective

Who – the protagonist.

Tim Cook , Chief Executive Officer (CEO) and former Chief Operating Officer (COO) of technology giant Apple Inc .

As of February 2020, Apple Inc. had revenues of approximately US$265 billion making it the most valued company on the planet. Its lead product was the iPhone, with over 1.6 billion sold since it was introduced in 2007. To cope with demand, Apple had a complex supply chain of 200 suppliers located in over 800 production facilities, across 43 countries.

With the smartphone market starting to mature, challenges by new competitors and, according to critics, no game-changing new products in development, Apple needed to take steps to diversify from its dependence on the iPhone.

Apple were planning to launch a new suite of services including entertainment, news, video games and financial services, so Tim Cook needed to consider what changes should be made to Apple’s global supply chain to support its strategic objectives. What capabilities would it need as Apple’s business model continued to evolve?

This case is set in February 2020, 44 years after the company was founded.

Apple’s primary iPhone suppliers include companies in the US, China, Japan, South Korea, Switzerland and the Netherlands, but 90% of product assembly is done in China before being transported back to the US.

It would be difficult for Tim Cook and Apple to duplicate the capabilities and advantages offered by its Chinese suppliers, but their diversification from iPhones into wearables and services would provide additional challenges. New supply chains for different products and technologies were required along with content for entertainment and streaming services. As Apple’s business model evolved, Cook had to ensure the global supply chain continued to support it.

AUTHOR PERSPECTIVE

This is the second win for P Fraser Johnson in the Production and Operations Management category for a case on Apple, following his win in 2016 . It is also the seventh award win for Ivey Business School.

Winning the award

Fraser said: “Naturally it is always terrific to be recognised in my profession by an outstanding organisation such as The Case Centre. With the many cases that are written each year in the operations management field, I was understandably surprised to hear that my Apple case was the 2022 winner of The Case Centre Award for my discipline.

“As a professor at the Ivey Business School, the ability to write cases that resonate with students and instructors is a critical aspect of my job and career. Writing cases that instructors want to adopt in their courses helps promote the use of the case method, which is incredibly important to me personally.”

Case popularity

He continued: “I think this case stands out for two reasons. First, it effectively describes the evolution of Apple as an organisation, through the good times and bad times, and how its supply chain strategy evolved and became a critical strength and capability. Everyone knows about Apple and the products that the company makes. The case makes students think about how Apple has been able to support its business and product strategies through unique supply chain capabilities.

“Second, the case is supported with a thorough teaching note. Effective teaching notes are essential in helping instructors deliver a great classroom experience with the case.”

Writing the case

Fraser explained: “First, this case is based on published sources. Gathering data from a wide range of sources is important. Accessing published articles, press releases, analyst reports and financial records are but a few avenues.

“Second, keep the case focused on a central topic and avoid extraneous information. It is easy to load the case up with interesting data, but it needs to be relevant to the issue(s) in the case.

“Lastly, have the case focused on a decision. Do not tell a story, the newspapers can handle that job. Students should use the issue(s) and decision, in the role of the protagonist, to focus their analysis. Without a decision in the case, students will not be able to properly structure their analysis and preparation.”

Case writing advice

He continued: “A case on a company with a well-known brand name helps, but there are two other important factors. First, the issue in the case needs to be interesting and relevant, which helps provide the basis for a good class discussion. Second, a strong teaching note helps provide instructors with thorough analysis and guidance on how to deliver the case in the classroom.”

Teaching the case

Fraser commented: “This case is one of the most popular in my supply chain elective. Apple is the largest company in the world (by market capitalisation) a brand that every student is familiar with – as a result students have views about the company, both positive and negative. Students can then relate their personal experience with the information in the case. It is an easy case to teach with a lot of discussion.”

The protagonist

Educators can login to view a free educator preview copy of this case and its teaching note.

View all the 2022 winners

Stay in touch with all the latest case news and views in our free newsletter, Connect .

Read it online or sign up to have it delivered direct to your inbox!

Discover more

Apple Case Study: Supply Chain, Design Thinking, & More

Do you know that Apple earns nearly one hundred thousand dollars per minute? This information may not be surprising because Apple is the world’s most valuable company. However, there are numerous challenges the corporation has faced on its way to success. You can learn many business lessons by doing the Apple case study, and we are here to help!

- 🍏 Apple Inc Facts

- 👍 Apple Case Study – Best Ideas

- 📝 Supply Chain

- 🍀 Sustainability

- 👩 Human Resource Management

- 🎨 Design Thinking and Innovation

- 💻 Crisis Management

- 🔝 Apple Case Study – 50 Best Examples

🔗References

🍏 6 fun facts about apple inc.

- There has been a mystery surrounding the brand’s name. However, the word ‘Apple’ simply came from the founder, Steve Jobs’ favorite fruit.

- Originally Apple had three co-founders: Steve Jobs, Steve Wozniak, and Ronald Wayne. Ronald Wayne left the company only 12 days after its foundation. One of our free business essays discusses Apple and its leadership style.

- Apple employs more than 154,000 people, which could be a good-sized town population! Millions more people make money from selling Apple products in local shops.

- Apple’s first company logo was a drawing of the father of physics, Isaac Newton.

- The creator of the iPod, Tony Fadel, initially offered the device to Real Networks and Philips, but they turned it down.

- Apple created the digital color camera. The Apple QuickTake was introduced in 1994 and was one of the first consumer digital cameras.

👍 Best Ideas for an Apple Case Study

Numerous internal and external factors influence Apple company’s financial performance. When doing the Apple case study, choose the sphere that interests you the most and think of what can be improved. Here’s a list of topics that may pique your curiosity:

- The history of Apple company.

- Corporate values of Apple.

- Key Apple’s products and services.

- Importance of technology and innovation in Apple.

- Apple’s corporate identity.

- Apple’s online presence and e-marketing.

- Apple’s supply chain.

- Labor practices in Apple.

- Apple’s executive management.

- Apple’s strategic management.

- The role of Apple’s board of directors.

- Apple’s privacy policy.

- Marketing strategies in Apple.

- Apple’s financial figures over the years.

- Apple’s eco-initiatives.

- Criticism of Apple.

- Apple’s customer support.

- HR strategy in Apple.

- Apple’s crisis management strategy.

- Apple’s primary competitors.

📝 Apple Supply Chain Case

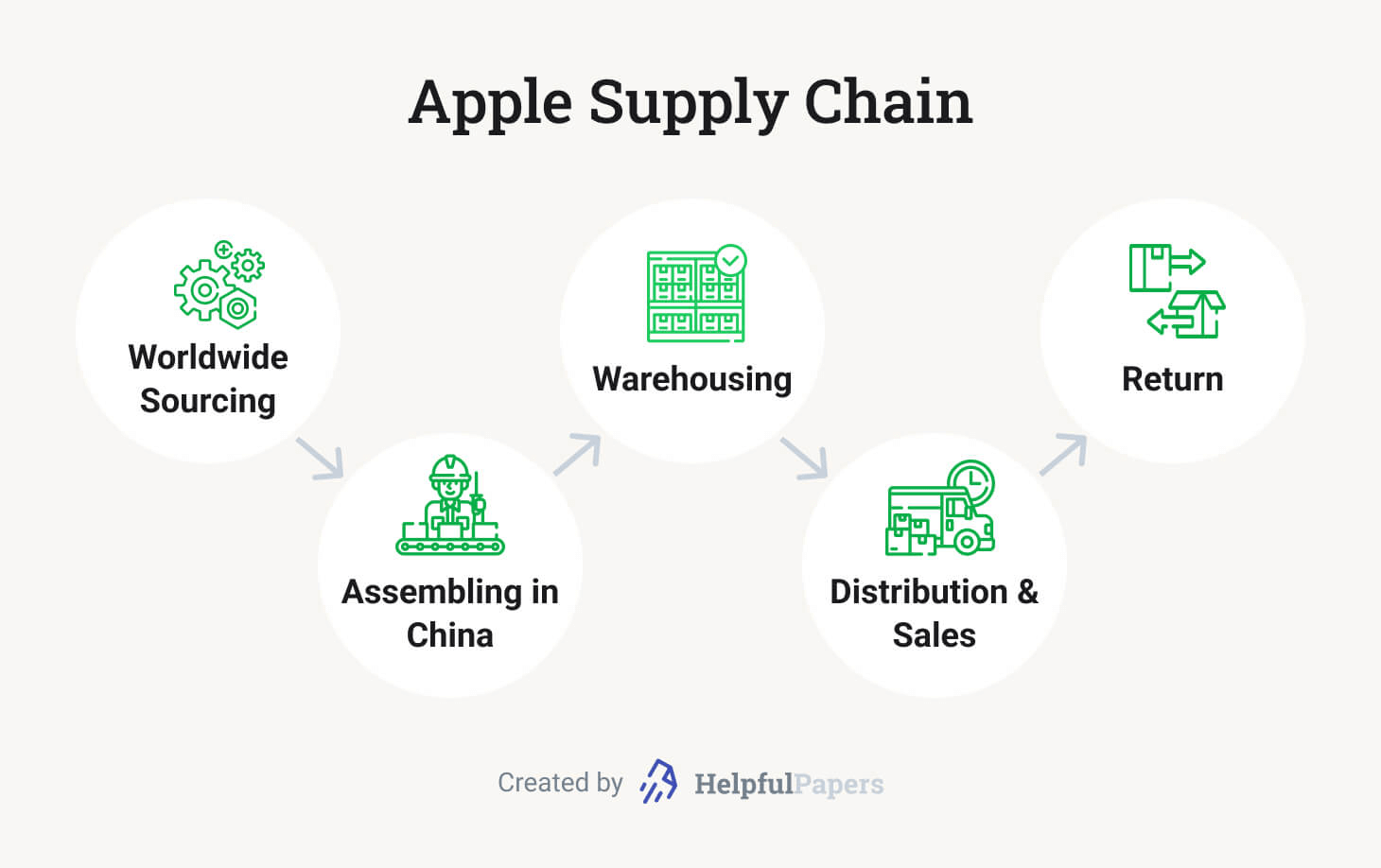

- How does Apple organize its supply chain operations? Apple buys components and materials from various suppliers worldwide. Then the company gets them shipped to the assembling plant in China. From there, products go directly to retail stores and consumers who buy online.

- Main advantages of Apple’s inventory management Apple’s strategy is to keep as little inventory on hand as possible. The company can’t afford to keep too many products in stock because a sudden move from a competitor or an innovation can dramatically decrease the value of products in inventory.

- Apple’s use of multiple suppliers Apple has an extensive network of suppliers in its supply chain in 31 countries worldwide. It allows the company to successfully mitigate disruptions or delays and process large volumes of pre-orders.

- What can other businesses learn from Apple’s supply chain strategy? The main advantage of Apple’s supply chain is the multiple suppliers strategy. Businesses should be encouraged to use alternative suppliers to reduce single-supplier risks and improve financial performance.

🍀 Sustainability of Apple

- Apple lowers the use of carbon materials Since the creation of the iPhone in 2007, the company has sold over 1.5 billion units. To make the iPhone design more energy-efficient, the company developed an innovation. They created “Dave,” a recycling robot that recovers rare materials such as earth magnets from old phones.

- Apple’s use of renewable energy Moving to renewable energy is a crucial component of Apple’s green policies. Apple’s headquarters in California is 100% powered by solar panels. It contributes to a positive effect on pollution globally and locally.

- Apple is innovative in its materials Apple works closely with two aluminum suppliers to develop the first carbon-free aluminum process. They have already forged highly low-carbon aluminum used for parts and components in MacBook Pro.

- Apple reduces the use of conflict materials A common source of “conflict minerals” is the Democratic Republic of Congo, an area with ongoing human rights violations. Apple has ceased relationships with mineral providers that fail to be certified as ethical and conflict-free.

👩 Apple’s Human Resource Management

- Apple’s human resources strategies The HR specialists of Apple always seem to hire diverse, independent, and talented employees. Most of the employees are provided with training once they join the company. Apple encourages workers to build self-reliance and practical skills to ensure they are mentally ready to jump from one big project to another.

- Apple’s cultural values and employees’ growth Apple is one of the biggest job creators in the US, providing positions for designers, marketers, hardware and software engineers, scientists, etc. Apple offers considerable opportunities to its employees to climb the career ladder and develop free-thinking and creativity.

- Employees’ rewarding system in Apple Apple runs Apple Fellow Program to recognize employees’ significant contributions to the company. Those employees are rewarded and later on designated as team leaders. The company also provides competitive wages, monthly benefits, and periodical grants that serve as a reward to the best employees.

🎨 Design Thinking and Innovation at Apple

- Apple adopting design thinking Design thinking is a human-oriented approach to innovation that Apple applies. This principle is used to achieve innovation considering the consumer at all the development stages. Apple adopts design thinking by considering the form and function of its products.

- Apple’s user-friendly products When it comes to understandability, Apple successfully integrated it into its products. Apple designs products that are easy to use so that new users rarely consult manuals or guides. Apple highlights that they build user-friendly products rather than complex, hard-to-use ones.

- The simplicity behind Apple’s products One of defining characteristics of Apple’s design is simplicity. The company designs its products to look clean, simple, and straightforward. At the same time, Apple products are instantly recognizable at first glance and have now become status symbols.

- Apple designs for the future When it comes to design, Apple is a pioneer. The company’s design team start working on a new design two years beforehand. So, when Apple introduces a new, cutting-edge design, competitors will not have a chance to copy it.

💻 Apple Crisis Management Case Study

- FBI asked Apple for unlimited access to any iPhone user in 2015 After the tragic San Bernardino terrorist attack in 2015, the US government demanded Apple release a new iOS, which would give them access to users’ private information. Apple refused this demand by writing a public letter. In this letter, the company highlighted that they always put the customer first.

- Apple’s supply chain crisis in 2021 At the beginning of October, most of China shuts down for the Golden Week holidays. Phone and iPad assembly was halted for several days due to supply chain constraints and restrictions on the use of power. Consequently, Apple was forced to scale back its total production goal for 2021. This crisis illustrates how external factors can influence even tech giants like Apple.

- Apple’s plan to get through the COVID-19 crisis At the beginning of the pandemic, CEO Tim Cook stressed the company’s plan to keep its eyes on the road and its hands on the wheel. The goal was to keep investing in developing future products and services no matter what. For example, Apple has been working on how an Apple Watch can provide any warning of Covid-infections.

🔝 Apple Case Studies – 50 Best Examples

- HP Company and Apple: financial statement analysis. This essay analyzes two US companies in the computer hardware and software industry, the Hewlett Packard Company and Apple Inc.

- Financial research report Apple, Inc. The purpose of this economic research report is to evaluate the financial records of Apple for investment purposes.

- Income statement: Apple and Samsung. Check out this comparative analysis of the two IT giants in five dimensions: net income, net sales, operating expenses, income tax, and selling and administrative expenses.

- Apple Inc.: the cost accounting. The paper aims to analyze the cost accounting model of Apple Inc. In simple words, cost accounting calculates a company’s total cost of production.

- Apple’s success in the customer electronics industry. This essay explores Apple’s strategic management and planning that help the company maintain leadership.

- The sustainability of Apple’s success. Apple’s market presence stretches beyond American borders. This essay will teach you the peculiarities of Apple’s strategic decision-making.

- The case deal with Apple’s successes. This study explores Apple’s key competitive advantages, such as product differentiation and efficient distribution channels.

- Apple, Inc. financial performance analysis. This is a financial performance analysis for Apple, which provides insights for creditors and investors on a company’s financial health.

- Apple company system strategy analysis. This essay investigates Apple’s most important information systems: office automation, enterprise resource planning, and data warehouse systems.

- A case study in managerial accounting: Apple Inc. Every organization aims to maximize revenue while minimizing costs. This article explores how Apple uses budgeting tools to estimate the total charges in various business processes.

- Analysis of Apple’s marketing mix. This paper studies the development and significance of each element of Apple’s marketing mix to determine its relevance to the company’s mission.

- Cash flow management at Apple Inc. The essay analyzes the financial statements of Apple, including non-cash items, to accurately reflect on an organization’s financial health.

- The human resource plan of Apple Inc. This writing describes the latest cultural change at Apple Inc. and how such an initiative has transformed its performance and profitability.

- Management accounting at Apple. Learn more about the use of accounting information by Apple’s managers within an organization to guide them in making concrete decisions.

- Apple iPhone: demand and supply. This paper aims to analyze the law of supply and demand on the example of the Apple iPhone, a product that has changed the technology market.

- The process of hiring employees at Apple. This essay analyzes recruitment and selection processes, such as job advertisement and interviewing at Apple, Inc.

- Apple’s performance & customer satisfaction with iPhones. Curren’s study follows how Apple succeeds in the competitive business environment by maintaining a pool of loyal customers by delivering quality products and services.

- Apple Inc.: smartphone industry. This report focuses on Apple’s primary segment of sales and marketing, which are the iPhones, a globally recognized product and brand.

- Apple’s competitive positioning. The purpose of this paper is to critically evaluate the company’s existing competitive positioning and suggest how it can be improved.

- Performance management at Apple Inc. This passage discusses linkages between employee performance, HR practices, and organizational performance at Apple Inc.

- Apple Inc.’s strategies throughout its history. This essay is dedicated to Apple’s innovative and effective ways of doing business in different company eras.

- Apple and Dell companies: inventory management. This study focuses on the methods employed by Apple’s managers to maintain the optimum level of stock for the company.

- Apple’s customers and their behavior. This essay aims to understand the decision-making process of Apple’s buyers, taking into consideration psychological and economic factors.

- Apple company: innovation action plan. This sample discusses the innovation opportunities and challenges that are facing the company.

- The financial ratio of Apple and Samsung. For this report, two competitor firms have been selected to review and analyze their financial performance.

- Analysis of Apple’s website: fundamental aspects.

- Strategic management at Apple Inc.

- Apple’s production management.

- Apple’s music streaming future service strategies.

- Ipad by Apple Inc.

- Contemporary developments in business and management of Apple.

- Apple stores retail mix analysis.

- Marketing communication used by Apple.

- Apple iPod product’s marketing audit & management.

- Apple and Microsoft companies’ marketing approaches.

- Apple company managing innovation & entrepreneurship.

- Branding in Apple incorporation.

- Apple Inc. managing technology and innovation.

- Apple Inc.’s development since the 1980s.

- Apple Inc: why it has success?

- Apple incorporation’s managerial economics.

- Apple Inc.’s modeling decision-making.

- Apple Inc.’s analysis and implications for practice.

- Apple company in the Chinese market.

- Apple Inc.’s products and customer dissatisfaction.

- Apple Inc.’s marketing communication scenarios.

- Apple company’s corporate communications.

- Apple company communication system strategies.

- Apple Inc.’s supply chain and recommendations.

- Apple Inc.’s new steps toward competitiveness.

- Operations and Supply Chain

- The Case for Making Multiple Suppliers Part of Your Supply Chain Strategy

- Environment – Apple – apple

- Apple’s Supply Chain: The 9 Major Companies

- Apple and Amazon further climate commitments as sustainability race heats up

Ford Pinto Case Study & Other Analysis Ideas

Mcdonald’s supply chain issues – a case study on supply and demand analysis.

Supply Demand Management

Add a favorite.

Don’t have an Apple ID?

- Create one now

- Forgot your Apple ID or password?

Key Qualifications

- - Proven records of delivering diverse and complex process re-engineering projects from conception through implementation, with deep understanding in system implementation and development life cycles.

- - Proficient in R/Python, VBA and SQL development. Capable to combine supply chain practices, problem solving thought process, and data analytics to show insights.

- - Good communication and interpersonal skill, flexible and open to different ideas, able to establish trust and reach alignment quickly.

- - Self-motivated individual who thrives working in a global, matrix, fast-paced environment, good at negotiation and drive clarify through ambiguity.

- - Forward thinking; able to see beyond the corner to identify risks / opportunities and drive project teams toward the desired objective.

- - System implementation experience in sales & operations / demand planning for manufacturing or high-tech industry is preferred.

- - Knowledge of Apple Script, web framework (e.g. Django, Flask), front-end technologies (e.g. Vue) and machine learning is a plus.

Description

Education & experience, additional requirements.

- Apple is an equal opportunity employer that is committed to inclusion and diversity. We also take affirmative action to offer employment and advancement opportunities to all applicants, including minorities, women, protected veterans, and individuals with disabilities. Apple will not discriminate or retaliate against applicants who inquire about, disclose, or discuss their compensation or that of other applicants.

20 Must-Know Supply Planner Interview Questions (With Answers)

Common Supply Planner interview questions, how to answer them, and sample answers from a certified career coach.

Congratulations—you’ve been invited to interview for a supply planning job! A supply planner plays an important role in any business, as they ensure the right resources are available at the right time.

To make sure you’re prepared for your upcoming interview, read on for some of the most common questions asked of supply planners. We’ll give you example answers and tips that will help you ace the interview and get the job.

- What strategies do you use to forecast demand and plan inventory levels?

- Describe your experience with developing supply chain models for different scenarios.

- How do you ensure that the right products are available in the right quantities at the right time?

- Explain how you would go about optimizing a company’s supply chain network.

- What is your experience with managing supplier relationships?

- Are you familiar with any software or tools used to manage supply planning processes?

- How do you handle unexpected changes in customer demand or supply disruptions?

- What strategies do you use to identify cost savings opportunities within the supply chain?

- Describe a situation where you had to negotiate with suppliers to get better terms.

- How do you stay informed of industry trends and developments related to supply planning?

- What metrics do you use to measure the performance of the supply chain?

- How do you approach setting up an effective system for tracking orders and shipments?

- What strategies do you use to reduce lead times and improve delivery accuracy?

- How do you handle working with multiple stakeholders when it comes to supply planning decisions?

- What steps do you take to ensure compliance with relevant regulations and standards?

- Do you have experience with implementing new technologies into the supply chain process?

- How do you prioritize tasks when faced with conflicting demands from customers and suppliers?

- What strategies do you use to minimize risk in the supply chain?

- Describe a time when you had to troubleshoot a problem with a shipment.

- How do you handle working with international suppliers?

1. What strategies do you use to forecast demand and plan inventory levels?

Interviewers want to know that you’re familiar with the supply planning process and have strategies in place to manage inventory levels. This question allows you to demonstrate your knowledge of the supply planning process and your ability to apply it to the company’s specific needs. You should be able to discuss forecasting methods, inventory optimization techniques, and strategies for managing supply chain disruptions.

How to Answer:

To answer this question, you should explain the process that you use to forecast demand and plan inventory levels. You can start by discussing your forecasting methods such as trend analysis or time series models. Then, you should discuss how you optimize inventory levels based on those forecasts. Talk about any strategies you have in place for managing supply chain disruptions, such as building relationships with suppliers or maintaining a buffer stock of inventory. Finally, be sure to emphasize the importance of communication with stakeholders throughout the process.

Example: “When forecasting demand, I use a combination of trend analysis and time series models to identify patterns in past sales data. This allows me to anticipate customer needs more accurately and plan inventory levels accordingly. To optimize inventory levels, I employ a variety of strategies such as ABC classification and safety stock calculations. Additionally, I build strong relationships with suppliers so that we can quickly respond to any supply chain disruptions. Communication is key throughout the process—I make sure stakeholders are informed every step of the way.”

2. Describe your experience with developing supply chain models for different scenarios.

Supply planners need to be able to anticipate potential disruptions in their supply chain and develop models to mitigate their impact. They use forecasting and analytics to evaluate the performance of suppliers and develop strategies to reduce costs and improve efficiency. By asking this question, the interviewer wants to understand your experience and expertise in this area.

Start by discussing the processes and tools you use to forecast demand. Explain how you analyze historical data, customer trends, market conditions, and other factors to develop accurate forecasts. Talk about any software or systems you are familiar with that help you plan inventory levels. Finally, touch on your experience in developing strategies for mitigating supply chain disruptions.

Example: “I have extensive experience in developing supply chain models for different scenarios. I use a variety of forecasting techniques, including time-series analysis and regression analysis, to predict future demand. I also leverage various software programs, such as SAP APO and Excel, to develop accurate forecasts. Additionally, I’m experienced in creating strategies to mitigate the impact of potential disruptions in the supply chain. For example, I recently developed a model that identified weak points in our supplier network and proposed solutions to reduce costs and improve efficiency.”

3. How do you ensure that the right products are available in the right quantities at the right time?

Supply planners must be able to balance customer demand with the availability of materials and resources. The interviewer will be looking for evidence that you have a sound knowledge of supply chain management and that you can accurately forecast and predict customer demand. They will also be interested in hearing about any methods or techniques you use to ensure that the right items are available for sale in the right quantities.

You should be prepared to discuss how you use data and analytics to forecast customer demand and plan for the right product mix. You may also want to mention any techniques you use to monitor inventory levels, such as using automated systems or conducting regular stock checks. Be sure to emphasize your ability to balance customer needs with available resources and explain how you prioritize tasks to ensure that items are available when they’re needed.

Example: “I use a combination of data analysis and forecasting techniques to ensure that the right products are available in the right quantities at the right time. I monitor customer demand trends, inventory levels, lead times, and supplier performance to make sure that we have the necessary items on hand when customers need them. I also prioritize tasks based on urgency and importance so that items are always available when they’re needed. Additionally, I stay up to date on industry news and changes in customer preferences so that I can anticipate any potential shifts in demand and adjust our product mix accordingly.”

4. Explain how you would go about optimizing a company’s supply chain network.

An effective supply chain network is essential for any company that wants to maximize efficiency and profitability. Interviewers want to gauge your problem-solving skills and your knowledge of the supply chain process. This question gives them insight into your thought process and your ability to identify and analyze issues to find the best possible solution.

Start by explaining the steps you would take to identify areas of improvement in the supply chain. This could include analyzing current processes, evaluating existing suppliers and vendors, looking for opportunities to reduce costs or increase efficiency, and identifying any potential risks. Then explain how you would use your findings to create a plan of action to optimize the company’s supply chain network. Be sure to emphasize your ability to think critically and come up with creative solutions to complex problems.

Example: “When I’m tasked with optimizing a company’s supply chain network, the first thing I do is conduct an analysis of their existing processes and vendors. I then evaluate each supplier based on quality, cost, and delivery speed to identify areas where there could be improvement. Once I have identified potential opportunities, I create a plan that outlines the steps necessary to optimize the system. This includes researching new suppliers and negotiating better terms, streamlining processes, and implementing technology solutions to increase efficiency. Above all, my goal is to develop a supply chain network that reduces costs while still providing our customers with high-quality products in a timely manner.”

5. What is your experience with managing supplier relationships?

Supply planners need to have a good understanding of how to manage relationships with suppliers. This includes understanding how to negotiate with them, how to secure competitive prices and delivery terms, and how to ensure that all shipments arrive on time. This question allows the interviewer to gauge your experience in this area.

Talk about any past experience you have working with suppliers. This could include your ability to negotiate favorable terms, how well you understand the supplier market and pricing dynamics, or any successful projects that you’ve completed related to supplier management. If you don’t have much experience in this area, focus on your skills and abilities that would make you a successful supply planner. For example, highlight your problem-solving skills, your ability to multitask, or your attention to detail.

Example: “In my current role as a supply planner, I’m responsible for managing relationships with suppliers. I have experience negotiating competitive prices and delivery terms, while ensuring that all shipments arrive on time. My problem-solving skills and attention to detail enable me to identify potential areas of risk and address any issues proactively. Additionally, my strong organizational skills allow me to keep track of multiple supplier relationships simultaneously. In the past, I’ve successfully managed projects related to supplier management, such as reducing costs by 10% through renegotiating contracts.”

6. Are you familiar with any software or tools used to manage supply planning processes?

Supply chain planning requires a lot of coordination and communication between different departments, and often requires an understanding of different software and tools to track and manage all the different pieces. This question is designed to test your familiarity with the software and tools that you may need to use in a supply chain planning role.

Depending on the company, you may need to be familiar with specific software or tools used in supply chain planning. Be sure to research what software and tools the company uses before your interview so that you can answer this question confidently. If you don’t have direct experience with the software or tools they use, talk about similar software and tools you are familiar with, and explain how those skills could transfer over to the role. Additionally, emphasize any past experiences where you successfully managed a complex supply chain process.

Example: “I have extensive experience working with ERP software, such as SAP and Oracle. I also have a good understanding of the supply chain planning process, including forecasting and inventory management. In my previous role, I successfully managed a complex supply chain process that involved multiple vendors and customers across different countries. My familiarity with these tools and processes will allow me to hit the ground running in this new position.”

7. How do you handle unexpected changes in customer demand or supply disruptions?

Supply planning requires you to be able to quickly and effectively adjust plans in response to changes in customer demand or supply disruptions. The interviewer wants to know that you can think on your feet, come up with creative solutions, and collaborate with stakeholders in order to minimize any impacts to the business.

Start by talking about past experiences you’ve had with handling unexpected changes in customer demand or supply disruptions. Talk through the steps you took to identify and address the issue, as well as any solutions you implemented. If you haven’t had a situation like this arise before, focus on how you would approach it if faced with a similar challenge. Explain how you would assess the situation, analyze data, communicate with stakeholders, and develop a plan of action.

Example: “If faced with an unexpected change in customer demand or supply disruption, I would first assess the situation to identify the root cause. Once I have a better understanding of the problem, I would analyze the data and develop a plan of action that takes into consideration the potential impact on customers, suppliers, and other stakeholders. Then, I would communicate this plan to all relevant parties and collaborate with them to ensure we are working together towards a successful resolution. In my previous role as a Supply Planner for XYZ Corporation, I had to handle a sudden surge in customer demand which required us to adjust our production and delivery schedules. By quickly assessing the issue, analyzing data, and collaborating with stakeholders, we were able to successfully meet customer demands without compromising quality.”

8. What strategies do you use to identify cost savings opportunities within the supply chain?

Supply planners are tasked with the difficult job of balancing supply and demand while trying to minimize costs. By asking this question, the interviewer is looking to see if you have a deep understanding of the supply chain and how to identify cost savings opportunities. The interviewer also wants to know if you’re familiar with different supply chain processes, such as inventory management and vendor management, and how they can be optimized to reduce costs.

This is a great opportunity to showcase your knowledge of the supply chain. You can start by talking about how you identify cost savings opportunities, such as through analyzing data and trends or monitoring supplier performance. You may also want to discuss strategies for optimizing inventory management, such as reducing lead times or using just-in-time manufacturing. Finally, you can talk about vendor management techniques, such as negotiating better terms with suppliers or consolidating vendors to reduce costs.

Example: “When it comes to identifying cost savings opportunities within the supply chain, I like to start by analyzing data and trends to identify areas of potential savings. I also believe in closely monitoring supplier performance to ensure that they are meeting our expectations in terms of quality and on-time delivery. Additionally, I use strategies such as reducing lead times, using just-in-time manufacturing, and negotiating better terms with suppliers to reduce costs. I also believe in consolidating vendors when possible in order to leverage better prices and terms from them. Overall, I’m always looking for ways to optimize the supply chain and make it more efficient and cost-effective.”

9. Describe a situation where you had to negotiate with suppliers to get better terms.

Negotiating prices and terms with suppliers is a major part of a supply planner’s job. Interviewers want to know that you’re capable of finding the best deals for your organization, and that you can think strategically about how to leverages your relationships with suppliers. Knowing how to negotiate and build strong relationships with suppliers is key for any supply planner.

Before you answer this question, think about a situation where you negotiated with suppliers to get better terms. This could be anything from negotiating prices or payment terms to agreeing on delivery dates or quality standards. Talk through the steps you took in that particular instance and how it resulted in an improved arrangement for your organization. Be sure to emphasize any tangible results of your negotiation—such as cost savings or increased efficiency—so that hiring managers can see the impact of your work.

Example: “I recently had to negotiate with a supplier to get better terms for my organization. We had been working with them for several years, but their prices had gone up significantly and we needed to find a way to reduce our costs. I worked with them to develop a long-term agreement that included reduced prices, more flexible payment terms, and improved delivery schedules. As a result, we were able to save the organization over 10% on our total spend with that supplier.”

10. How do you stay informed of industry trends and developments related to supply planning?

Supply planning can be a complex and ever-changing job, and it requires a certain level of expertise. The interviewer wants to see that you stay on top of the latest trends and news so that you can make informed decisions about how to optimize the supply chain. They’ll want to know what publications and blogs you read, what conferences and trade shows you attend, and what other sources you use to stay informed.

Staying informed of industry trends and developments is essential for supply planners. You should be able to demonstrate your knowledge of the latest news, research and technology related to supply planning. Explain how you keep up with industry changes by reading relevant publications and attending conferences or webinars. Additionally, mention any professional associations or networks that you are a part of so that the interviewer can get an idea of your involvement in the field. Lastly, explain how you use this information to make decisions and develop strategies in your current role.

Example: “I stay informed of industry trends and developments related to supply planning by reading industry publications, attending conferences and webinars, and staying active in professional networks. For example, I’m a member of the International Supply Chain Management Association and attend their conferences and webinars regularly. I also read Supply Chain Management Review and other industry publications to stay up-to-date on the latest developments and trends. Additionally, I use this information to inform my decision-making and develop strategies in my current role as a supply planner, such as optimizing the supply chain to reduce costs and increase efficiencies.”

11. What metrics do you use to measure the performance of the supply chain?

This is a great question to ask supply planners because it gives them a chance to demonstrate their knowledge of the supply chain and the metrics they use to measure its performance. Supply planners must have a good understanding of the metrics and the processes they use to measure performance, so the interviewer wants to know that you have the skills needed to do the job.

Start by talking about the metrics you use to measure supply chain performance. These can include inventory turnover, on-time delivery, cost of goods sold, and lead times. Explain how each metric is used to assess the effectiveness of the supply chain and how it helps you make decisions. You should also discuss any tools or systems you use to track these metrics, such as an enterprise resource planning (ERP) system. Finally, explain how you use the data from these metrics to identify areas for improvement in the supply chain and develop strategies to increase efficiency.

Example: “I use a variety of metrics to measure the performance of the supply chain. I track inventory turnover, on-time delivery, cost of goods sold, and lead times to get a comprehensive picture of how the supply chain is performing. I also use an ERP system to capture and analyze data from these metrics. This helps me identify areas for improvement and develop strategies to increase efficiency in the supply chain. I also use the data to forecast demand and adjust production levels accordingly.”

12. How do you approach setting up an effective system for tracking orders and shipments?

This question is looking for an understanding of the fundamentals of supply chain management. You’ll need to be able to explain the process of tracking orders and shipments, from the moment they’re placed to the moment they’re received by the customer. The interviewer will also want to hear about your experience with logistics software, inventory tracking systems, and other related tools.

Start by explaining the process of tracking orders, from beginning to end. Be sure to include details on how you use logistics software and inventory tracking systems to monitor shipments. If you’ve implemented any processes or tools to improve order tracking, be sure to mention those as well. Finally, wrap up your answer with a discussion of the importance of accurate and timely order tracking and how it contributes to customer satisfaction.

Example: “I approach setting up an effective system for tracking orders and shipments by first identifying the key stakeholders and their needs. I then research and select the most appropriate software and systems to meet those needs, such as logistics and inventory tracking systems. I take into account the cost, complexity, and scalability of the system, as well as the customer’s needs. I also ensure that the system is regularly updated and monitored so that orders and shipments can be tracked in real-time. I understand the importance of accurate and timely order tracking in order to maintain customer satisfaction, so I always strive to ensure that the process is as efficient and reliable as possible.”

13. What strategies do you use to reduce lead times and improve delivery accuracy?

Supply planning is a critical role for any organization, as it involves anticipating what materials will be needed and ensuring they’re available when needed. The interviewers want to know that you understand the strategies involved in managing a supply chain and can anticipate the needs of the organization. By asking this question, they’re hoping to get a sense of the strategies you’ve used in the past to reduce lead times and improve delivery accuracy.

The best way to answer this question is to provide specific examples of how you’ve used strategies in the past to reduce lead times and improve delivery accuracy. For example, you could talk about how you implemented a Just-in-Time inventory system or created an automated ordering process. You should also explain the results of your efforts—such as reduced lead times by X%, improved delivery accuracy by Y%, etc.—so that the interviewer can get a better sense of the impact of your work.

Example: “I’ve had great success in reducing lead times and improving delivery accuracy by implementing a Just-in-Time inventory system. By monitoring stock levels and ordering items only when needed, I was able to reduce lead times by 20%, while also increasing delivery accuracy by 10%. I’ve also implemented an automated ordering process that ensures that orders are sent out as soon as they’re placed, which has resulted in a further 10% reduction in lead times and a 5% improvement in delivery accuracy. I’m confident that I can use the same strategies to reduce lead times and improve delivery accuracy in your organization.”

14. How do you handle working with multiple stakeholders when it comes to supply planning decisions?

Supply planning requires strong collaboration between different departments and stakeholders. This question is designed to assess how you handle working with multiple people, how you manage competing priorities, and how you make decisions when there is no clear answer. The interviewer wants to know that you have the interpersonal and organizational skills to effectively manage the supply chain process.

To answer this question, you should talk about your experience working with multiple stakeholders in the past. Describe how you were able to effectively communicate and collaborate with each stakeholder while managing competing priorities. Show that you understand the complexities of supply planning decisions and can handle difficult conversations when necessary. Finally, emphasize your ability to make decisions even when there is no clear answer.

Example: “I have extensive experience working with multiple stakeholders on supply planning decisions. I understand the complexities of the process and am comfortable engaging with stakeholders from different departments. My ability to effectively communicate and collaborate with each stakeholder is an asset when it comes to making decisions. I also understand the importance of making decisions even when there is no clear answer, and I am able to weigh all the options and make an informed decision based on the available data. I believe my experience makes me an ideal candidate for this position.”

15. What steps do you take to ensure compliance with relevant regulations and standards?

Supply planners are responsible for ensuring that goods are shipped and received in a timely manner while adhering to the relevant regulations and standards. This question allows the interviewer to assess your understanding of the importance of compliance, as well as your ability to think through the steps you take to ensure that your processes are compliant. It also provides an opportunity for you to demonstrate your knowledge of any relevant regulations and standards.

To answer this question, you should provide a detailed overview of the steps you take to ensure compliance. This might include researching relevant regulations and standards, discussing them with colleagues or other stakeholders, and implementing processes that adhere to those regulations and standards. Additionally, you can discuss any tools or systems you use to track compliance, such as software applications or databases. Finally, be sure to explain how your efforts have resulted in successful outcomes for your organization.

Example: “I take a comprehensive approach to ensure compliance with relevant regulations and standards. First, I research and become familiar with the relevant regulations and standards, which I then discuss with colleagues to ensure that everyone is on the same page. I then create detailed processes and procedures that adhere to these regulations and standards, and I use a variety of tools, such as software applications and databases, to track compliance. I also regularly review and update these processes and procedures to make sure that they are up to date. My efforts have resulted in successful outcomes for my organization, such as reduced delivery times and improved quality control.”

16. Do you have experience with implementing new technologies into the supply chain process?

Technology is an integral part of supply chain planning. Automation and optimization of processes are key to success in this role, so the interviewer will want to know if you have any experience with implementing new technologies. They’ll also be looking for evidence of your ability to think strategically and to make decisions that will help optimize the supply chain process.

You should be prepared to discuss any experience you have with implementing new technologies into the supply chain process. Talk about how you identified areas for improvement and implemented solutions that increased efficiency, accuracy, and/or cost savings. If you don’t have direct experience, then talk about your ability to research and learn new technologies quickly, as well as your willingness to take on challenging projects.

Example: “Yes, I have experience with implementing new technologies into the supply chain process. In my previous role as a supply planner, I was responsible for researching and evaluating new technologies that could be used to optimize the supply chain process. After identifying areas of improvement, I worked with the IT team to implement new systems and software that increased efficiency, accuracy, and cost savings. Additionally, I was able to quickly learn and use new technologies, enabling me to stay up-to-date with the latest industry trends and best practices. I believe my experience and ability to learn quickly make me an ideal candidate for this role.”

17. How do you prioritize tasks when faced with conflicting demands from customers and suppliers?

Supply planners must juggle various demands from customers, suppliers, and other stakeholders. They need to be able to prioritize tasks and find ways to meet all of these demands without sacrificing quality or customer service. This question allows the interviewer to gauge your ability to handle multiple tasks and respond quickly to changing conditions.

You should be prepared to discuss how you prioritize tasks in a way that meets the needs of all involved. Talk about your ability to create a plan and stick to it, while remaining flexible enough to make changes when needed. You can also discuss any strategies you have for dealing with conflicting demands from customers and suppliers, such as negotiating terms or finding creative solutions. Finally, emphasize your commitment to customer service and quality assurance.

Example: “When faced with conflicting demands from customers and suppliers, I prioritize tasks by first assessing the urgency of the request and then evaluating the impact it will have on customer satisfaction and quality. I then create a timeline and plan that meets the demands of both customers and suppliers, while also allowing for flexibility in case of any changes. I believe in providing the highest level of customer service and quality, so I always strive to ensure that all parties are satisfied with the outcome.”

18. What strategies do you use to minimize risk in the supply chain?

The supply chain is a complex system and managing it requires being able to anticipate and plan for any potential risks. This question seeks to understand what strategies you have used in the past to minimize the chances of disruptions and delays in the supply chain. It also helps the interviewer understand your ability to think strategically and your experience with risk management.

To answer this question, you should discuss the strategies and techniques that you have used to minimize risk in your supply chain. Examples of these strategies include diversifying suppliers, having a backup plan for any potential disruptions, implementing contingency plans, monitoring supplier performance, and utilizing analytics to predict future trends. Additionally, you can also mention how you have developed relationships with key stakeholders such as customers and suppliers in order to ensure smooth operations.

Example: “In my role as a supply planner, I always strive to minimize risk in the supply chain. I do this by diversifying my suppliers, monitoring supplier performance, and utilizing analytics to predict any potential disruptions. Additionally, I have developed strong relationships with my customers and suppliers in order to ensure smooth operations. I am also experienced in developing contingency plans and backup plans in case of any unexpected events. With these risk management strategies, I am confident that I can help minimize disruptions in the supply chain and ensure smooth operations.”

19. Describe a time when you had to troubleshoot a problem with a shipment.

Supply planners need to be ready to tackle any kind of problem related to shipments. This could include issues with suppliers, shipping delays, or incorrect orders. By asking this question, the interviewer wants to know if you can think on your feet and come up with creative solutions to these kinds of problems.

For this answer, you should focus on a specific problem that you solved and the steps you took to solve it. Talk about how you identified the issue, then explain any research or investigation you did to find out more information. Finally, discuss what solution you came up with and how it worked out in the end. If possible, use an example of a time when you saved money for the company by troubleshooting a shipment issue.

Example: “One time I was working on a shipment of materials from a supplier that was delayed due to a shipment error. I immediately started doing research to find out what had happened, and I discovered that the supplier had mislabeled the shipment and sent it to the wrong address. I quickly contacted the supplier and was able to get the shipment re-routed to the correct address. This saved the company both time and money, as the shipment was able to arrive on time and we didn’t have to pay for the additional shipping costs.”

20. How do you handle working with international suppliers?

Working with international suppliers requires a specific set of skills. It’s not just about managing the complexities of cross-border regulations and logistics, but also understanding the cultural differences that can influence the way these suppliers do business. Interviewers will want to know if you have the knowledge and experience to handle these tasks with the utmost care and efficiency.

Start by talking about the international suppliers you’ve worked with in the past. Explain how you navigated different cultures, regulations, and logistics to ensure successful outcomes. You should also talk about any specific challenges you faced and how you overcame them. If you don’t have direct experience working with international suppliers, explain what steps you would take to build relationships with them and manage any potential issues that may arise.

Example: “I have a lot of experience working with international suppliers. I’ve had success negotiating with suppliers in China, India, and Mexico and understand the nuances of different cultures and regulations. I take the time to build relationships with suppliers and am always mindful of cultural differences when interacting with them. I also stay up to date on any changes in regulations and logistics to ensure that shipments arrive on time and in the best condition. I’ve also had success streamlining processes to make sure that our suppliers are meeting our needs in terms of quality and cost.”

20 Records Management Interview Questions and Answers

20 major gifts officer interview questions and answers, you may also be interested in..., 20 common chief product officer interview questions and answers, 30 estimation engineer interview questions and answers, 20 security dispatcher interview questions and answers, 20 customer service analyst interview questions and answers.

- Study Guides

- Homework Questions

6-2 Assignment Global Supply Chain Case Study inter

IMAGES

VIDEO

COMMENTS

Despite having no prior experience in supply chain management or demand-supply forecast, I decided to pursue this challenge anyways. Below is how the process went: 1) 15-minute phone call with the recruiter 2) 45-minute phone interview with a senior member of the team, focused 50% in behavioral and experience and 50% in case study discussion.

Has anyone interviewed for the supply demand planner at Apple? How was your experience? Looking for tips.

I was a demand planner for mccormick. Yeah man really remember the star method and go through the question using it. If you have any experience with excel or certifications bring that up. Focus on strengths with problem solving and communication. A lot of it is collaborating with other teams like finance and supply planners.

The process took 3 months. I interviewed at Apple in 2/1/2022. Interview. 1. Recruiter reached out to me on LinkedIn 2. Screening call with the recruiter 3. Received an excel file with a case study and had 3 days to answer questions laid out in the file 4. Phone interview with a manager (half behavioral, half case study) 5.

11 Apple Supply And Demand Planer interview questions and 11 interview reviews. Free interview details posted anonymously by Apple interview candidates.

The Supply Demand Planner will develop, communicate, and execute end-to- end product demand and supply plans across all channels of distribution in over 80 countries for a current or future product line. Product line assignments will be made at the time of hire in any of Apple's multi-billion dollar businesses, including Mac, Watch, iPad ...

Description. •You will forecast demand, inventory, and multi-channel sell through. Generate weekly and quarterly supply plans that meet Apple's financial objectives. Evaluate risks. Plan and implement contingency plans to mitigate. •You'll analyze product sales and find opportunities to drive partner groups to appropriate action.

The worldwide demand planner will be responsible for the demand forecasting and planning for a part of the AppleCare business. You are comfortable in working with cross-functional teams and in using analytics to improve forecasting methods. You will be required to analyze large amounts of data, identify significant trends, and adjust to meet an ...

This case focuses on the supply chain strategy of Apple Inc. (Apple). Set in early 2020, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to develop an understanding of Apple's source of competitiveness and to gain insights into the management of a large, complex global supply chain network that focused on the ...

Apple is well-known for its innovations in hardware, software, and services. Thanks to them, it grew from some 8,000 employees and $7 billion in revenue in 1997, the year Steve Jobs returned, to ...

1) Apple's Supply Chain Model Information about Apple Supply Chain is a bit here, there and everywhere, it's kinda tough to find the actual case study. To the best of my knowledge, many business schools still use the case study "Apple Computer's Supplier Hubs: A Tale of Three Cities" from Stanford University (1996).

New. Thuy98nic Sep 14, 2023. Hi, can you share about the case study, what should I prepare. Thanks. Hello Blinders, I have upcoming interviews with the apple supply demand planner team and was wondering if I could hear people's perspective on the process, culture and trajectory in this team. Also, they mentioned a case study as part of the ...

I have an upcoming interview for a WorldWide Supply Demand Chain Planner position at Apple that requires a technical portion of the interview, as well as a full case study later on. Can someone familiar with the role describe the day to day and what to expect in terms of technical parts of the supply demand interview?

Worldwide Supply Demand Planner (Current Employee) - Cupertino, CA - June 24, 2013. Ops / Supply Chain at Apple is a challenging and fast-paced environment. You will learn a lot and gain a lot of new skills but you will also have to give up a lot to be successful at apple. There is essentially no work-life balance in ops / supply chain roles.

Apple's Annual Report (SEC Filing) of 2011 is analyzed and simplified supply chain processes are constructed as below; Supply Chain Planning at Apple Inc. Supply Chain Planning at Apple Inc is the classic example of the New Product Development Process (NPD). It's the integration of R&D, Marketing and various function under supply chain ...

9 Apple Demand Planner interview questions and 8 interview reviews. Free interview details posted anonymously by Apple interview candidates. ... Next was a case study test and they gave us some time to send the slide deck back to the HR. ... 9 entretiens pour le poste de Supply Chain demand Planner recruter sur LinkedIn par la rh d'Apple pour ...

As of February 2020, Apple Inc. had revenues of approximately US$265 billion making it the most valued company on the planet. Its lead product was the iPhone, with over 1.6 billion sold since it was introduced in 2007. To cope with demand, Apple had a complex supply chain of 200 suppliers located in over 800 production facilities, across 43 ...

Despite having no prior experience in supply chain management or demand-supply forecast, I decided to pursue this challenge anyways. Below is how the process went: 1) 15-minute phone call with the recruiter 2) 45-minute phone interview with a senior member of the team, focused 50% in behavioral and experience and 50% in case study discussion.

Design thinking is a human-oriented approach to innovation that Apple applies. This principle is used to achieve innovation considering the consumer at all the development stages. Apple adopts design thinking by considering the form and function of its products. Apple's user-friendly products.

The China Supply Demand Planning Analyst will be the liaison between Apple's vast data points and the key decisions that drive end-to-end product demand and supply plans across all distribution channels in over 80 countries. You will work with a globally dispersed multi-functional team to conduct business analysis to implement new supply ...

Apple iPhone: A Market Case Study. Daylin Van De Vliert. Abstract. Founde d in 1976, Apple inc. quickly became one ofhe biggest companies in the world. Throughout the years, Apple has been a part ...

4. Explain how you would go about optimizing a company's supply chain network. An effective supply chain network is essential for any company that wants to maximize efficiency and profitability. Interviewers want to gauge your problem-solving skills and your knowledge of the supply chain process.

17 Apple Ww Supply Demand Planner interview questions and 13 interview reviews. Free interview details posted anonymously by Apple interview candidates.

Apple Inc. Supply and Demand Apple is a U.S. multinational company that specializes in manufacturing and marketing of electronic products. Top Apple brands include iPhone, iPod, Apple Computer, and iPad. Globally, Apple is ranked as the second largest global electronic company with over $215.6 Billion revenue at the end of the 2016 fiscal year.

1 6-2 Assignment: Global Supply Chain Case Study Evelyn Pabon Professor Zhang NT-220 - Global Dimensions in Business February 28, 2024 The case study of "Apple and its suppliers" delves into the relationship between the company's social responsibility and the actions of its suppliers. The workers were subjected to excruciatingly long working hours and were forced to endure terrible working ...