- Reference Manager

- Simple TEXT file

People also looked at

Mini review article, gas sensing performance of in 2 o 3 nanostructures: a mini review.

- 1 Hubei Key Laboratory for Processing and Application of Catalytic Materials, School of Physics and Electronic Information, Huanggang Normal University, Huanggang, China

- 2 Hubei Key Laboratory of Ferro and Piezoelectric Materials and Devices, Faculty of Physics and Electronic Sciences, Hubei University, Wuhan, China

Effective detection of toxic and hazardous gases is crucial for ensuring human safety, and high-performance metal oxide-based gas sensors play an important role in achieving this goal. In 2 O 3 is a widely used n-type metal oxide in gas sensors, and various In 2 O 3 nanostructures have been synthesized for detecting small gas molecules. In this review, we provide a brief summary of current research on In 2 O 3 -based gas sensors. We discuss methods for synthesizing In 2 O 3 nanostructures with various morphologies, and mainly review the sensing behaviors of these structures in order to better understand their potential in gas sensors. Additionally, the sensing mechanism of In 2 O 3 nanostructures is discussed. Our review further indicates that In 2 O 3 -based nanomaterials hold great promise for assembling high-performance gas sensors.

1 Introduction

In recent decades, there has been growing attention to the effective monitoring of air quality due to the increasingly serious environmental problems ( Ma et al., 2016 ; Zhang et al., 2018 ; Ge et al., 2019 ). Even toxic gases with low concentrations can be harmful to human health ( Park et al., 2016 ; Cordero et al., 2018 ; Zhou et al., 2022 ). For example, the toxic gas formaldehyde (HCHO) can cause serious blurred vision and vertigo when its concentration exceeds 0.1 mg/m 3 ( Peng and Huang, 2022 ). In the workplace, the concentration of n-butanol should be kept below 152 mg/m 3 to ensure the safety of human lives ( Zhao et al., 2021 ). In addition, a high risk of explosion may occur if the concentration of H 2 reaches 4%–75% in the air ( Phanichphant, 2014 ). It should be noted that many toxic, hazardous, or flammable gases are odorless, colorless, and tasteless, which means they cannot be detected by humans directly ( Wetchakun et al., 2011 ; Chi et al., 2014 ; Shi et al., 2018 ). Therefore, high-performance gas sensors are of great importance to effectively detect these gases and their concentrations in the air.

Metal oxide-based gas sensors have become a popular research topic in recent years due to their advantages of low cost, easy of fabrication, low power consumption and high sensor response to a wide range of gases ( Xu and Cheng, 2016 ; Lu et al., 2019 ; Nikolic et al., 2020 ). Nanostructured metal oxides always presented high specific surface areas and could provide abundant active sites on their surfaces ( Zhang et al., 2017 ; Srinivasan et al., 2019 ; Walker et al., 2019 ). This positive factor effectively promotes the adsorption and the diffusion of gas molecules in the sensing materials, resulting in the excellent gas sensing performances of nanostructured metal oxides. For instance, in the study conducted by Zhu et al., CuO nanoflowers demonstrated a significantly higher sensor response of 123.4 to 50 ppm H 2 S at 80°C compared to CuO-based microspheres, which only showed a sensor response of 4.36 ( Hu et al., 2017 ; Hu et al., 2018a ). Chen et al. also reported superior sensing performance of ZnO-based nanostructures with a sensor response as high as 6043 to 100 ppm triethylamine (TEA) at an optimal working temperature of 183.5°C, when compared to ZnO films (with a response of ∼22.5) or hierarchical ZnO microspheres (with a response of 242) ( Shen et al., 2018 ; Liu et al., 2021a ; Li et al., 2021 ). Furthermore, the net-like SnO 2 nanoarrays showed a response time of only 16.3 s to 10 ppm H 2 S at 350°C, which was approximately ten times lower than that of SnO 2 films (167.8 s) ( Ge et al., 2022 ). Thus, outstanding gas sensing properties could be expected through synthesizing nanostructured metal oxides.

In 2 O 3 is another popular n-type metal oxide that possesses a wide band gap of 3.5–3.7 eV ( Vuong et al., 2014 ; Han et al., 2015 ; Park, 2017 ). Its outstanding thermal stability, high conductivity, and excellent chemical/physical properties make it a promising candidate for gas detection ( Liang et al., 2015 ; Kumar et al., 2021 ; Meng et al., 2022 ). For example, Zhang et al. successfully prepared Ni-doped In 2 O 3 -based nanocubes through a hydrothermal method, achieving effective detection of 20 ppm HCHO with a response time of 76 s at room temperature ( Zhang et al., 2020 ). The research conducted by Han et al. demonstrated that the sensor response of In 2 O 3 nanorods doped with Co could be improved to 23.2 towards 10 ppm HCHO at 130 C ( Wang et al., 2018 ). Additionally, flower-like In 2 O 3 nanomaterials exhibited a sensor response and response time of 3.1 and 53 s, respectively, to 0.5 ppm isoprene at 190°C ( Han et al., 2020 ). A Google Scholar survey with keywords of “nano + In 2 O 3 +gas sensor” revealed that from 2017 to 2022, there were 826, 878, 919, 1060, 1210, and 1520 papers published on the topic. Although the data obtained may not be entirely accurate, the increasing number of published references highlights the growing attention given to In 2 O 3 -based gas sensors in recent years. Therefore, summarizing the recent developments in In 2 O 3 -based gas sensors would be meaningful to better understand their advantages in gas sensing.

In this paper, we have chosen several highly cited published references to conduct a mini review on typical In 2 O 3 -based gas sensors. Our focus was mainly on summarizing and comparing the high-performance characteristics of these gas sensors. Furthermore, we presented the methods used to prepare various In 2 O 3 -based materials. Additionally, we provided a brief review of the gas sensing mechanism for In 2 O 3 -based gas sensors.

2 Research status of gas sensing performances of recent In 2 O 3 nanostructures

2.1 pristine in 2 o 3 -based nanomaterials.

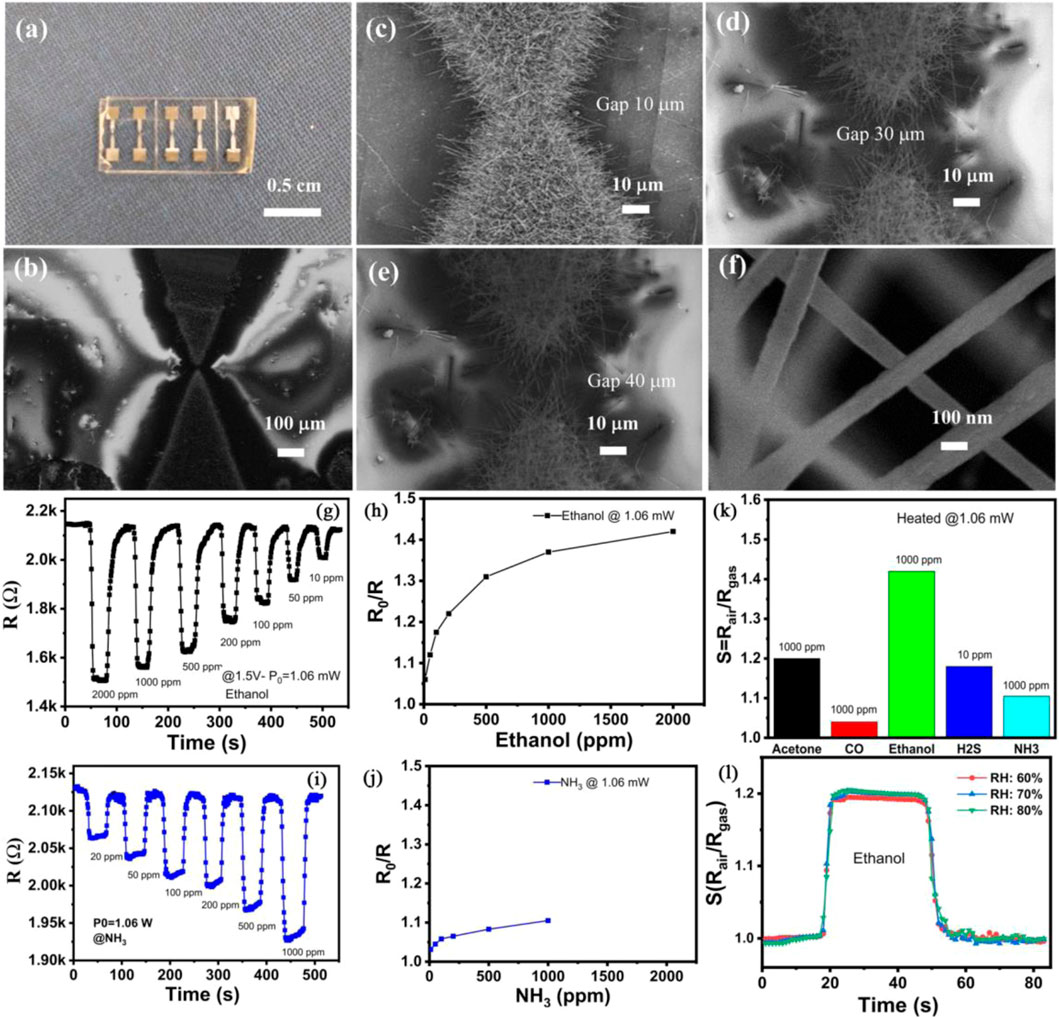

A novel self-heated gas sensor for detecting ethanol at room temperature was assembled by Nguyen et al. using In 2 O 3 nanowires ( Son et al., 2022 ). The sensor utilized the Joule effect generated by the In 2 O 3 nanowires under an operating voltage to achieve self-heating during operation. The In 2 O 3 nanowires were synthesized via a one-chip growth technique of thermal evaporation. The gap between the prepared electrodes was designed to be 10, 30 or 40 µm ( Figures 1A, B ), with the corresponding devices labeled as sensor-10, sensor-30, or sensor-40, respectively. Results showed that the well-crystallized In 2 O 3 nanowires were successful to bridge the gap of electrodes ( Figures 1C–E ). The In 2 O 3 nanowires had an average diameter of ∼100 nm and an average length of over 10 µm ( Figure 1F ). Sensor-40 exhibited better ethanol sensing performance compared to sensor-10 or sensor-30. Sensor-40 showed a superior sensing performance to 10–2000 ppm ethanol compared to NH 3 under a supplied power of 1.06 mW ( Figures 1G–J ). The sensor response of sensor-40–2000 ppm ethanol was ∼1.45. Meanwhile, the sensor response of sensor-40–1000 ppm ethanol was higher than that to 1000 ppm acetone, CO, H 2 S or NH 3 ( Figure 1K ), indicating good gas selectivity of the In 2 O 3 nanowires. Additionally, the sensor response of sensor-40 to ethanol was not significantly affected by humidity levels of 60%, 70%, or 80% ( Figure 1L ).

FIGURE 1 . (A) Digital image of the assembled gas sensor. (B) SEM image of a gas sensor. (C–E) SEM image of In 2 O 3 nanowires grown at electrodes with gasps of 10, 30 and 40 μm, respectively. (F) High magnification SEM of In 2 O 3 nanowires. (G, H) Dynamic gas sensing performance and sensor response (I, J) of sensor-40 to 10–2000 ppm ethanol or NH 3 at room temperature. (K) Selective gas sensing performance of sensor-40. (L) ethanol gas sensing behavior of sensor-40 under different humidity. Reprinted with permission from ref. ( Son et al., 2022 ). Copyright 2022, Elsevier.

Shboul et al. have developed a novel gas sensor mainly composed of solution-printed In2O3 nanoparticles ( Al Shboul and Izquierdo, 2021 ). In their study, In 2 O 3 nanoparticles, copper acetate (CuAc), graphite (Gt) flakes, and polystyrene (PS) were added to 10 mL of xylene to form a stable paste. The paste was then spread over a flexible PET substrate with prepared carbon electrodes to assemble the gas sensor. The In 2 O 3 -based sensor (SS), without CuAc, showed unresponsive sensing performance to H 2 S showed unresponsive sensing behavior towards H 2 S with concentrations below 100 ppb. The sensor response of the SS was only 2–100 ppb H 2 S, and the response time was as long as ∼25 min. The In 2 O 3 -based sensing material with 10 wt% CuAc (MS10) exhibited better sensing performance than sensing materials with 2 wt% CuAc (MS2), 25 wt% CuAc (MS25), or 50 wt% CuAc (MS50). The sensor response of the MS10 was found to be ∼18–100 ppm H 2 S at room temperature, with a relative humidity of ∼30%.

The study by Pham et al. also showed the potential of porous In 2 O 3 nanorods for detecting CO gas at 350°C ( Van Tong et al., 2021 ). The nanorods were synthesized via a hydrothermal method at 180°C for 10 h, and showed a sensor response of 3.46–400 ppm CO with a response and recovery time of 41/43 s. Similarly, Zhang et al. employed a surfactant-assisted co-precipitation method to prepare hierarchical branch-like In 2 O 3 nanomaterial for detecting ozone (O 3 ) ( Sui et al., 2021 ). The resulting hierarchical branch-like In 2 O 3 showed a high sensor response of 44–100 ppb O 3 at its optimum working temperature of 70°C.

2.2 In 2 O 3 -based composites

2.2.1 in 2 o 3 composited with noble metals.

Wang et al. have investigated the impacts of Au, Ag, Pt, and Pd on the ethanol gas sensing performance of long-range mesoporous In 2 O 3 ( Cheng et al., 2021 ). They synthesized the ordered mesoporous In 2 O 3 by replicating the structure of SBA-15, and then prepared Au, Ag, Pt, or Pd-doped In 2 O 3 through an in-situ doping routine. The mesoporous In 2 O 3 doped with Pd exhibited a specific surface area of 94.22 m 2 /g, significantly higher than that of pristine In 2 O 3 (64.55 m 2 /g), Au-doped In 2 O 3 (78.29 m 2 /g), Ag-doped In 2 O 3 (67.52 m 2 /g), or Pt-doped In 2 O 3 (76.41 m 2 /g). Similarly, the pore diameter for the Pd-doped In 2 O 3 was 3.6 nm, also larger than that for pristine In 2 O 3 (2.6 nm). The high specific surface area and large pore diameter are favorable for improving gas molecule adsorption and diffusion in the sensing material. Consequently, the concentration of chemisorbed oxygen species in Pd-doped In 2 O 3 was the highest among all samples, reaching 54.8%. The sensor based on Pd-doped In 2 O 3 also demonstrated the best performance for 100 ppm ethanol at an operating temperature of 200–350°C. The sensor response of Pd-doped In 2 O 3 was 39 at 250°C, higher than that of pristine In 2 O 3 (∼5), Au-doped In 2 O 3 (∼7.5), Ag-doped In 2 O 3 (∼15), or Pt-doped In 2 O 3 (∼17.5). Furthermore, Pd-doped In 2 O 3 exhibited higher sensor response to 100 ppm ethanol than to 100 ppm ammonia, methanol, toluene, benzene, acetone, formaldehyde, or ethanol, revealing excellent sensing selectivity.

The research conducted by Zhang et al. showed that an excellent hydrogen sensing performance could be achieved with the use of Tb-doped In 2 O 3 nanocomposites decorated with Ag (Ag-Tb-In 2 O 3 ) ( Bai et al., 2022 ). In their study, the Ag-modified Tb-doped In 2 O 3 nanocomposite was successfully synthesized through a hydrothermal process combined with a facile annealing method. Interestingly, the material exhibited two coexisting crystalline phases, including the hexagonal phase In 2 O 3 (h-In 2 O 3 ) and the cubic phase In 2 O 3 (c-In 2 O 3 ). Further analysis of the XRD patterns confirmed that the Tb was doped within the In 2 O 3 while the Ag was decorated on the surface of the nanocomposite. The Tb doping was found to reduce the grain sizes of both c-In 2 O 3 and h-In 2 O 3 , resulting in the generation of oxygen vacancies in the nanocomposite. Consequently, the Ag-Tb-In 2 O 3 nanocomposite exhibited a better sensing performance for 500 ppb H 2 at operating temperatures ranging from 120 to 200°C. The sensor response of the Ag-Tb-In 2 O 3 was found to be 4.63–500 ppb H 2 at its optimum operating temperature of 160°C, which is higher than that of the pristine In 2 O 3 (∼1.5), Tb-doped In 2 O 3 (∼2.5), or Ag-decorated In 2 O 3 (∼3.5).

2.2.2 In 2 O 3 composited with metal oxides

The study by Xie et al. demonstrated that the hydrogen sensing performance of In 2 O 3 nanotubes could be significantly enhanced by co-doping them with PdO and NiO ( Luo et al., 2021 ). Pristine In 2 O 3 and In 2 O 3 doped with NiO, PdO or NiO/PdO were synthesized using an electrospinning method. All four samples exhibited sensing performances to 5 ppm hydrogen gas at 160–300°C. Among them, the PdO/NiO-In 2 O 3 nanotubes showed the highest sensor response, with a value of 487.52 to 5 ppm H 2 at 160°C. In contrast, the sensor responses of pristine In 2 O 3 , NiO-In 2 O 3 , and PdO-In 2 O 3 were lower than 20. The response times of the pristine In 2 O 3 and NiO-In 2 O 3 were also relatively long, at 153 s and 97 s, respectively, which might not be suitable for rapid detection of hydrogen gas in practical applications. However, the addition of PdO significantly reduced the response time to only 1 s for both PdO-In 2 O 3 and PdO/NiO-In 2 O 3 , demonstrating the effectiveness of PdO in improving the response time of the In 2 O 3 -based material. Additionally, the incorporation of NiO reduced the recovery time of pristine In 2 O 3 (or PdO-In 2 O 3 ) from the original 232 s (or 674 s) to 168 s (or 336 s).

In a study by Wang et al., it was found that the ethanol gas sensing performance of In 2 O 3 nanoflowers could be significantly improved by combining them with metal-organic frameworks (MOF)-derived CO 3 O 4 ( Han et al., 2021 ). The In 2 O 3 nanoflowers were synthesized via a hydrothermal route at 150°C for 10 h. At the optimum operating temperature of 280°C, the CO 3 O 4 -In 2 O 3 nanoflowers exhibited a sensor response of over 5000 to 100 ppm ethanol. Similarly, the MOFs-derived porous Au@Cr 2 O 3 -In 2 O 3 nanorods were found to effectively detect 1 ppm isoprene with a sensor response of 6.4 at 180°C ( Wu et al., 2022 ).

2.2.3 In 2 O 3 composite with other materials

Song et al. reported an outstanding methanol sensing performance of In 2 O 3 nanocubes composited with Ti 3 C 2 T x MXene at room temperature ( Liu et al., 2021b ). The In 2 O 3 nanocubes were synthesized via a hydrothermal route at 140°C for 24 h, and the multilayer Ti 3 C 2 T x MXene was synthesized through etching the bulk MAX (Ti 3 AlC 2 ) phase with 10 mL HF solution (40 wt%). The In 2 O 3 nanocubes were modified with a cationic surfactant, (3-aminopropyl) triethoxysilane (APTES), to positively charge their surfaces. The positively charged In 2 O 3 nanocubes were then mixed with the Ti 3 C 2 T x MXene with negatively charged surfaces, and the mixture was treated under 120°C for a hydrothermal reaction. The In 2 O 3 /Ti 3 C 2 T x composite exhibited typical n-type gas sensing performance to ethanol at room temperature. However, the resistance of the composite after exposure to ethanol was unable to fully recover to its initial level in air, likely because residual methanol was not desorbed from the active site on the surface of the composite at room temperature. The sensor response of the composite to 5 ppm ethanol was ∼29.6 with a response/recovery time of 6.5/3.5 s. The composite also showed a promising gas sensing performance to 5–100 ppm ethanol and was not affected by relative humidity of ∼25–70%. The functional groups of the Ti 3 C 2 T x would be helpful in accelerating the adsorption of ethanol molecules, while the heterojunction between the In 2 O 3 and the Ti 3 C 2 T x could be another factor improving the ethanol gas sensing performance of the composite.

Song et al. also found that composting In 2 O 3 nanospheres with Ti 3 C 2 T x MXene nanosheets and Au could improve their HCHO sensing performance ( Liu et al., 2022 ). The Au-In 2 O 3 /Ti 3 C 2 T x composite exhibited a sensor response of approximately 31%, which is higher than that of the pristine Ti 3 C 2 T x (only ∼3.6%). Additionally, the response time and recovery time of the composite were as short as 5 s and 4 s, respectively, to 5 ppm HCHO at room temperature.

Zhu et al. reported an effective enhancement of the H 2 S sensing performance of In 2 O 3 nanocubes through the use of carbon canohorn (CNH) composites ( Zhou et al., 2022 ). The composite with a CNH mass concentration of 2 wt% (In 2 O 3 /CNH (2 wt%)) exhibited a high sensor response of 2906 to 2 ppm H 2 S at an optimum operating temperature of 70°C. Furthermore, the sensor response of the In 2 O 3 /CNH (2 wt%) to water vapor with 11%–95% humidity was not over 1.52, indicating that humidity did not significantly affect the sensing performance of the composite to H 2 S.

The use of In 2 O 3 -based nanomaterials as gas sensors has been well established, as discussed in the references above. The development of uniform two-dimensional In 2 O 3 nanomaterials may also lead to surprising gas sensing properties due to their large contact surface with air. Additionally, new materials can be explored to establish novel In 2 O 3 -based composites with heterostructure interfaces, leading to high-performance gas sensors. Careful investigation of the morphology and size effects of the second phase in the composite is essential to screen the best configuration for further improving gas sensing behavior. Machine learning algorithms can be applied to prepare In 2 O 3 -based gas sensors with excellent selectivity, and assembling several gas sensors in a gas sensor array can build a smart gas sensing system capable of simultaneously detecting several gases under mixed gas atmospheres.

3 Gas sensing mechanism of In 2 O 3 nanostructures

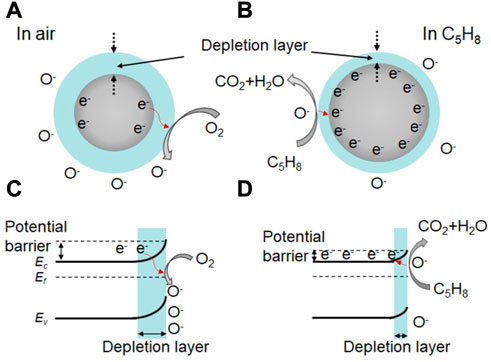

Understanding the gas sensing mechanism is crucial for the development of high-performance gas sensors based on In 2 O 3 . In general, the sensing performance of metal oxide-based sensors is attributed to the redox reaction between the adsorbed oxygen species (O 2 − , O − and O 2− ) and the target gas molecules ( Wang et al., 2018 ; Yang et al., 2018 ; Yang et al., 2019 ; Wang et al., 2020 ). For example, flower-like In 2 O 3 nanostructure have been shown to exhibit a promising sensor response of 3.1 towards 0.5 ppm isoprene at 190°C ( Han et al., 2020 ). In this case, oxygen gas is adsorbed on the active site, forming the adsorbed oxygen molecule in air (Eq. 1 ). Electrons are then transferred from the conductive bands of the flower-like In 2 O 3 nanostructure to the adsorbed oxygen molecule, forming adsorbed oxygen species (Eqs. 2–4 ; Figure 2A ). This leads to a bend in the band structure and the formation of a thick space-charge depletion layer at the surface region of the In 2 O 3 nanostructure ( Figure 2C ). Moreover, a high potential barrier is created between the contact flower-like In 2 O 3 nanostructure, resulting in a high resistance in air.

FIGURE 2 . (A, B) Schematic diagram of the isoprene sensing mechanism of In 2 O 3 nanostructure at 190°C, and the corresponding bending of band structures at the surface region of In 2 O 3 nanosturcture (C, D) .

When the target gas of isoprene is introduced into the testing chamber, the pre-adsorbed oxygen species react with the isoprene molecules (Eqs. 5, 6 ; Figure 2B ), releasing trapped electrons back to the In 2 O 3 nanostructure. As a result, the thickness of the space-charge depletion layer decreases ( Figure 2D ), and the potential barrier is also reduced between the contact flower-like In 2 O 3 nanostructure. This process leads to an effective reduction in the resistance of the sensor and a high sensor response to isoprene Similar theories apply to other In 2 O 3 -based sensors, including Ce-doped In 2 O 3 microspheres, CeO 2 -loaded In 2 O 3 hollow spheres, mesoporous In 2 O 3 , or Co-doped In 2 O 3 nanorods, which exhibit a promising sensing performance to glycol, H 2 , ethanol, or HCHO, respectively ( Hu et al., 2018b ; Liu et al., 2018 ; Wang et al., 2018 ; Cheng et al., 2021 ).

The high specific surface areas of the In 2 O 3 nanomaterials have been found to be beneficial in improving the adsorption of gas molecules ( Han et al., 2018 ; Tao et al., 2019 ; Cao et al., 2020 ). This increased surface area allows for more gas molecules to access the surface of In 2 O 3 nanomaterials, promoting the redox reaction between the adsorbed oxygen species and the target gas molecules. Additionally, the formation of a heterojunction between the main phase of In 2 O 3 and the introduced second phase in the composite can promote the transfer of electrons and holes across their surfaces, leading to the bending of their energy bands and the building of a high potential barrier ( Du et al., 2015 ; Ou et al., 2022 ). Modulating the height of this potential barrier can dramatically change the resistance of the composite, leading to improved sensing performance ( Feng et al., 2015 ). Overall, these two factors are commonly responsible for the high sensing performance of In 2 O 3 -based composites.

4 Conclusion

In this review, we provide a brief overview of current research on gas sensors based on In 2 O 3 nanostructures. Our analysis shows that uniform In 2 O 3 nanostructures with high specific surface areas generally exhibit superior gas sensing performance due to enhanced gas molecule adsorption and diffusion. Furthermore, the gas sensing properties of In 2 O 3 -based materials can be effectively enhanced by creating composites. Adding noble metals is a viable strategy for improving the interaction between gas molecules and In 2 O 3 , and metal oxides or Mxenes are widely used to further improve the gas sensing properties of In 2 O 3 nanostructures. The superior gas sensing performance of composites is primarily attributed to the high specific surface area and the formation of heterojunctions. Therefore, In 2 O 3 -based materials have immense potential for developing gas sensors with exceptional sensing capabilities.

Author contributions

All authors listed have made a substantial, direct and intellectual contribution to the work, and approved it for publication.

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51802109, 51972102, 52072115, and U21A20500) and the Department of Science and Technology of Hubei Province (Grant No. 2022CFB525).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Al Shboul, A. M., and Izquierdo, R. (2021). Printed chemiresistive In2O3 nanoparticle-based sensors with ppb detection of H2S gas for food packaging. ACS Appl. Nano Mater. 4, 9508–9517. doi:10.1021/acsanm.1c01970

CrossRef Full Text | Google Scholar

Bai, J., Kong, Y., Liu, Z., Yang, H., Li, M., Xu, D., et al. (2022). Ag modified Tb-doped double-phase In2O3 for ultrasensitive hydrogen gas sensor. Appl. Surf. Sci. 583, 152521. doi:10.1016/j.apsusc.2022.152521

Cao, J., Zhang, N., Wang, S., Chen, C., and Zhang, H. (2020). Researching the crystal phase effect on gas sensing performance in In2O3 nanofibers. Sensors Actuators B Chem. 305, 127475. doi:10.1016/j.snb.2019.127475

Cheng, P., Wang, Y., Wang, C., Ma, J., Xu, L., Lv, C., et al. (2021). Investigation of doping effects of different noble metals for ethanol gas sensors based on mesoporous In2O3. Nanotechnology 32, 305503. doi:10.1088/1361-6528/abf453

Chi, X., Liu, C., Liu, L., Li, S., Li, H., Zhang, X., et al. (2014). Enhanced formaldehyde-sensing properties of mixed Fe2O3–In2O3 nanotubes. Mat. Sci. Semicon Proc. 18, 160–164. doi:10.1016/j.mssp.2013.11.016

Cordero, J. M., Borge, R., and Narros, A. (2018). Using statistical methods to carry out in field calibrations of low cost air quality sensors. Sensors Actuators B Chem. 267, 245–254. doi:10.1016/j.snb.2018.04.021

Du, H., Wang, J., Sun, Y., Yao, P., Li, X., and Yu, N. (2015). Investigation of gas sensing properties of SnO2/In2O3 composite hetero-nanofibers treated by oxygen plasma. Sensors Actuators B Chem. 206, 753–763. doi:10.1016/j.snb.2014.09.010

Feng, C., Li, X., Ma, J., Sun, Y., Wang, C., Sun, P., et al. (2015). Facile synthesis and gas sensing properties of In2O3–WO3 heterojunction nanofibers. Sensors Actuators B Chem. 209, 622–629. doi:10.1016/j.snb.2014.12.019

Ge, C., Jin, C., Wang, M., Bai, L., Hussain, S., Qiao, G., et al. (2022). Template-derived net-like SnO2 nanoarrays for robust H2S sensing with broad-range linear response. Sensors Actuators B Chem. 366, 131991. doi:10.1016/j.snb.2022.131991

Ge, L., Mu, X., Tian, G., Huang, Q., Ahmed, J., and Hu, Z. (2019). Current applications of gas sensor based on 2-D nanomaterial: A mini review. Front. Chem. 7, 839. doi:10.3389/fchem.2019.00839

PubMed Abstract | CrossRef Full Text | Google Scholar

Han, B., Wang, J., Yang, W., Chen, X., Wang, H., Chen, J., et al. (2020). Hydrothermal synthesis of flower-like In2O3 as a chemiresistive isoprene sensor for breath analysis. Sensors Actuators B Chem. 309, 127788. doi:10.1016/j.snb.2020.127788

Han, D., Li, X., Zhang, F., Gu, F., and Wang, Z. (2021). Ultrahigh sensitivity and surface mechanism of gas sensing process in composite material of combining In2O3 with metal-organic frameworks derived Co3O4. Sensors Actuators B Chem. 340, 129990. doi:10.1016/j.snb.2021.129990

Han, D., Song, P., Zhang, S., Zhang, H., Xu, Q., and Wang, Q. (2015). Enhanced methanol gas-sensing performance of Ce-doped In2O3 porous nanospheres prepared by hydrothermal method. Sensors Actuators B Chem. 216, 488–496. doi:10.1016/j.snb.2015.04.083

Han, D., Zhai, L., Gu, F., and Wang, Z. (2018). Highly sensitive NO2 gas sensor of ppb-level detection based on In2O3 nanobricks at low temperature. Sensors Actuators B Chem. 262, 655–663. doi:10.1016/j.snb.2018.02.052

Hu, J., Sun, Y., Xue, Y., Zhang, M., Li, P., Lian, K., et al. (2018). Highly sensitive and ultra-fast gas sensor based on CeO2-loaded In2O3 hollow spheres for ppb-level hydrogen detection. Sensors Actuators B Chem. 257, 124–135. doi:10.1016/j.snb.2017.10.139

Hu, X., Zhu, Z., Chen, C., Wen, T., Zhao, X., and Xie, L. (2017). Highly sensitive H2S gas sensors based on Pd-doped CuO nanoflowers with low operating temperature. Sensors Actuators B Chem. 253, 809–817. doi:10.1016/j.snb.2017.06.183

Hu, X., Zhu, Z., Li, Z., Xie, L., Wu, Y., and Zheng, L. (2018). Heterostructure of CuO microspheres modified with CuFe2O4 nanoparticles for highly sensitive H2S gas sensor. Sensors Actuators B Chem. 264, 139–149. doi:10.1016/j.snb.2018.02.110

Kumar, V., Majhi, S. M., Kim, K. H., Kim, H. W., and Kwon, E. E. (2021). Advances in In2O3-based materials for the development of hydrogen sulfide sensors. Chem. Eng. J. 404, 126472. doi:10.1016/j.cej.2020.126472

Li, Z., Liu, X., Zhou, M., Zhang, S., Cao, S., Lei, G., et al. (2021). Plasma-induced oxygen vacancies enabled ultrathin ZnO films for highly sensitive detection of triethylamine. J. Hazard Mater 415, 125757. doi:10.1016/j.jhazmat.2021.125757

Liang, X., Kim, T. H., Yoon, J. W., Kwak, C. H., and Lee, J. H. (2015). Ultrasensitive and ultraselective detection of H2S using electrospun CuO-loaded In2O3 nanofiber sensors assisted by pulse heating. Sensors Actuators B Chem. 209, 934–942. doi:10.1016/j.snb.2014.11.130

Liu, J., Zhang, L., Fan, J., Zhu, B., and Yu, J. (2021). Triethylamine gas sensor based on Pt-functionalized hierarchical ZnO microspheres. Sensors Actuators B Chem. 331, 129425. doi:10.1016/j.snb.2020.129425

Liu, M., Sun, R., Sima, Z., Song, P., Ding, Y., and Wang, Q. (2022). Au-decorated In2O3 nanospheres/exfoliated Ti3C2Tx MXene nanosheets for highly sensitive formaldehyde gas sensing at room temperature. Appl. Surf. Sci. 605, 154839. doi:10.1016/j.apsusc.2022.154839

Liu, M., Wang, Z., Song, P., Yang, Z., and Wang, Q. (2021). In2O3 nanocubes/Ti3C2Tx MXene composites for enhanced methanol gas sensing properties at room temperature. Ceram. Int. 47, 23028–23037. doi:10.1016/j.ceramint.2021.05.016

Liu, X., Jiang, L., Jiang, X., Tian, X., Sun, X., Wang, Y., et al. (2018). Synthesis of Ce-doped In2O3 nanostructure for gas sensor applications. Appl. Surf. Sci. 428, 478–484. doi:10.1016/j.apsusc.2017.09.177

Lu, Z., Zhou, Q., Wei, Z., Xu, L., Peng, S., and Zeng, W. (2019). Synthesis of hollow nanofibers and application on detecting SF6 decomposing products. Front. Mater. 6, 183. doi:10.3389/fmats.2019.00183

Luo, Y., An, B., Bai, J., Wang, Y., Cheng, X., Wang, Q., et al. (2021). Ultrahigh-response hydrogen sensor based on PdO/NiO co-doped In2O3 nanotubes. J. Colloid Interf. Sci. 599, 533–542. doi:10.1016/j.jcis.2021.04.125

Ma, L., Fan, H., Tian, H., Fang, J., and Qian, X. (2016). The n-ZnO/n-In2O3 heterojunction formed by a surface-modification and their potential barrier-control in methanal gas sensing. Sensors Actuators B Chem. 222, 508–516. doi:10.1016/j.snb.2015.08.085

Meng, D., Qiao, T., Wang, G., Shen, Y., San, X., Li, R., et al. (2022). Rational design of CuO/In2O3 heterostructures with flower-like structures for low temperature detection of formaldehyde. J. Alloys Compd. 896, 162959. doi:10.1016/j.jallcom.2021.162959

Nikolic, M. V., Milovanovic, V., Vasiljevic, Z. Z., and Stamenkovic, Z. (2020). Semiconductor gas sensors: Materials, technology, design, and application. Sensors 20, 6694. doi:10.3390/s20226694

Ou, Y., Zhu, G., Liu, P., Jia, Y., Zhu, L., Nie, J., et al. (2022). Anchoring platinum clusters onto oxygen vacancy-modified In2O3 for ultraefficient, low-temperature, highly sensitive, and stable detection of formaldehyde. ACS sensors 7, 1201–1212. doi:10.1021/acssensors.2c00334

Park, S. (2017). Acetone gas detection using TiO2 nanoparticles functionalized In2O3 nanowires for diagnosis of diabetes. J. Alloys Compd. 696, 655–662. doi:10.1016/j.jallcom.2016.11.298

Park, S., Sun, G. J., Kheel, H., Lee, W. I., Lee, S., Choi, S. B., et al. (2016). Synergistic effects of codecoration of oxide nanoparticles on the gas sensing performance of In2O3 nanorods. Sensors Actuators B Chem. 227, 591–599. doi:10.1016/j.snb.2015.12.098

Peng, B., and Huang, X. (2022). Research status of gas sensing performance of Ti3C2Tx-based gas sensors: A mini review. Front. Chem. 10, 1037732. doi:10.3389/fchem.2022.1037732

Phanichphant, S. (2014). Semiconductor metal oxides as hydrogen gas sensors. Procedia Eng. 87, 795–802. doi:10.1016/j.proeng.2014.11.677

Shen, Z., Zhang, X., Mi, R., Liu, M., Chen, Y., Chen, C., et al. (2018). On the high response towards TEA of gas sensors based on Ag-loaded 3D porous ZnO microspheres. Sensors Actuators B Chem. 270, 492–499. doi:10.1016/j.snb.2018.05.034

Shi, S., Zhang, F., Lin, H., Wang, Q., Shi, E., and Qu, F. (2018). Enhanced triethylamine-sensing properties of P-N heterojunction Co3O4/In2O3 hollow microtubes derived from metal–organic frameworks. Sensors Actuators B Chem. 262, 739–749. doi:10.1016/j.snb.2018.01.246

Son, D. N., Hung, C. M., Le, D. T. T., Xuan, C. T., Van Duy, N., Dich, N. Q., et al. (2022). A novel design and fabrication of self-heated In2O3 nanowire gas sensor on glass for ethanol detection. Sensors Actuators A Phys. 345, 113769. doi:10.1016/j.sna.2022.113769

Srinivasan, P., Ezhilan, M., Kulandaisamy, A. J., Babu, K. J., and Rayappan, J. B. B. (2019). Room temperature chemiresistive gas sensors: Challenges and strategies—a mini review. J. Mater. Sci. Mater. Electron. 30, 15825–15847. doi:10.1007/s10854-019-02025-1

Sui, N., Zhang, P., Zhou, T., and Zhang, T. (2021). Selective ppb-level ozone gas sensor based on hierarchical branch-like In2O3 nanostructure. Sensors Actuators B Chem. 336, 129612. doi:10.1016/j.snb.2021.129612

Tao, Z., Li, Y., Zhang, B., Sun, G., Xiao, M., Bala, H., et al. (2019). Synthesis of urchin-like In2O3 hollow spheres for selective and quantitative detection of formaldehyde. Sensors Actuators B Chem. 298, 126889. doi:10.1016/j.snb.2019.126889

Van Tong, P., Hoang Minh, L., Van Duy, N., and Manh Hung, C. (2021). Porous In2O3 nanorods fabricated by hydrothermal method for an effective CO gas sensor. Mater Res. Bull. 137, 111179. doi:10.1016/j.materresbull.2020.111179

Vuong, N. M., Hieu, N. M., Kim, D., Choi, B. I., and Kim, M. (2014). Ni2O3 decoration of In2O3 nanostructures for catalytically enhanced methane sensing. Appl. Surf. Sci. 317, 765–770. doi:10.1016/j.apsusc.2014.08.125

Walker, J. M., Akbar, S. A., and Morris, P. A. (2019). Synergistic effects in gas sensing semiconducting oxide nano-heterostructures: A review. Sensors Actuators B Chem. 286, 624–640. doi:10.1016/j.snb.2019.01.049

Wang, J., Zhou, Q., Peng, S., Xu, L., and Zeng, W. (2020). Volatile organic compounds gas sensors based on molybdenum oxides: A mini review. Front. Chem. 8, 339. doi:10.3389/fchem.2020.00339

Wang, Z., Hou, C., De, Q., Gu, F., and Han, D. (2018). One-step synthesis of Co-doped In2O3 nanorods for high response of formaldehyde sensor at low temperature. ACS sensors 3, 468–475. doi:10.1021/acssensors.7b00896

Wetchakun, K., Samerjai, T., Tamaekong, N., Liewhiran, C., Siriwong, C., Kruefu, V., et al. (2011). Semiconducting metal oxides as sensors for environmentally hazardous gases. Sensors Actuators B Chem. 160, 580–591. doi:10.1016/j.snb.2011.08.032

Wu, X., Wang, H., Wang, J., Wang, D., Shi, L., Tian, X., et al. (2022). VOCs gas sensor based on MOFs derived porous Au@ Cr2O3-In2O3 nanorods for breath analysis. Colloids Surfaces A Physicochem. Eng. Aspects 632, 127752. doi:10.1016/j.colsurfa.2021.127752

Xu, J. M., and Cheng, J. P. (2016). The advances of Co 3 O 4 as gas sensing materials: A review. J. Alloys Compd. 686, 753–768. doi:10.1016/j.jallcom.2016.06.086

Yang, S., Song, Z., Gao, N., Hu, Z., Zhou, L., Liu, J., et al. (2019). Near room temperature operable H2S sensors based on In2O3 colloidal quantum dots. Sensors Actuators B Chem. 286, 22–31. doi:10.1016/j.snb.2019.01.110

Yang, W., Feng, L., He, S., Liu, L., and Liu, S. (2018). Density gradient strategy for preparation of broken In2O3 microtubes with remarkably selective detection of triethylamine vapor. ACS Appl. Mater. interfaces 10, 27131–27140. doi:10.1021/acsami.8b09375

Zhang, D., Cao, Y., Yang, Z., and Wu, J. (2020). Nanoheterostructure construction and DFT study of Ni-doped In2O3 nanocubes/WS2 hexagon nanosheets for formaldehyde sensing at room temperature. ACS Appl. Mater. interfaces 12, 11979–11989. doi:10.1021/acsami.9b15200

Zhang, H., Chen, W. G., Li, Y. Q., and Song, Z. H. (2018). Gas sensing performances of ZnO hierarchical structures for detecting dissolved gases in transformer oil: A mini review. Front. Chem. 6, 508. doi:10.3389/fchem.2018.00508

Zhang, Z., Zhu, L., Wen, Z., and Ye, Z. (2017). Controllable synthesis of Co3O4 crossed nanosheet arrays toward an acetone gas sensor. Sensors Actuators B Chem. 238, 1052–1059. doi:10.1016/j.snb.2016.07.154

Zhao, R., Wei, Q., Ran, Y., Kong, Y., Ma, D., Su, L., et al. (2021). One-dimensional In2O3 nanorods as sensing material for ppb-level n-butanol detection. Nanotechnology 32, 375501. doi:10.1088/1361-6528/ac06f6

Zhou, M., Yao, Y., Han, Y., Xie, L., Zhao, X., Barsan, N., et al. (2022). Ultrasensitive gas sensor based on nanocube In2O3-CNH composite at low operating temperature. Sensors Actuators B Chem. 354, 131224. doi:10.1016/j.snb.2021.131224

Keywords: In 2 O 3 , nanostructrues, gas sensor, sensing mechanism, review

Citation: Yang S, Yin H, Wang Z, Lei G, Xu H, Lan Z and Gu H (2023) Gas sensing performance of In 2 O 3 nanostructures: A mini review. Front. Chem. 11:1174207. doi: 10.3389/fchem.2023.1174207

Received: 26 February 2023; Accepted: 31 March 2023; Published: 07 April 2023.

Reviewed by:

Copyright © 2023 Yang, Yin, Wang, Lei, Xu, Lan and Gu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhigao Lan, [email protected] ; Haoshuang Gu, [email protected]

This article is part of the Research Topic

Low-Dimensional Nanomaterials toward Gas Sensing Application

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Micromachines (Basel)

Recent Progress in Gas Sensor Based on Nanomaterials

Associated data.

Not applicable.

Nanomaterials-based gas sensors have great potential for substance detection. This paper first outlines the research of gas sensors composed of various dimensional nanomaterials. Secondly, nanomaterials may become the development direction of a new generation of gas sensors due to their high sensing efficiency, good detection capability and high sensitivity. Through their excellent characteristics, gas sensors also show high responsiveness and sensing ability, which also plays an increasingly important role in the field of electronic skin. We also reviewed the physical sensors formed from nanomaterials in terms of the methods used, the characteristics of each type of sensor, and the advantages and contributions of each study. According to the different kinds of signals they sense, we especially reviewed research on gas sensors composed of different nanomaterials. We also reviewed the different mechanisms, research processes, and advantages of the different ways of constituting gas sensors after sensing signals. According to the techniques used in each study, we reviewed the differences and advantages between traditional and modern methods in detail. We compared and analyzed the main characteristics of gas sensors with various dimensions of nanomaterials. Finally, we summarized and proposed the development direction of gas sensors based on various dimensions of nanomaterials.

1. Introduction

The twenty-first century is an era of electronic information technology, and the high development of electronic technology has completely changed human society’s way of life. At the same time, the application of high-efficiency gas sensors in various fields, such as substance detection, is extremely critical now and in the future. However, certain problems are being faced in the development of gas sensors. At present, the quality and working efficiency of gas sensors are relatively low, and there are problems such as the aging process and the unreasonable process. To produce efficient and stable gas sensors, it is essential to select quality materials. Nanomaterials make full use of their far lower scale and excellent characteristics than regular devices and ideally become the core of gas sensor manufacturing materials. Nano-sensors have advanced analysis to the atomic scale, which broadens the application fields of sensors and promotes their production level.

After introducing nanotechnology into the field of gas sensors, it has significantly enhanced the selectivity, improved the sensitivity, reduced the working temperature, and improved the detection performance of gas sensors, as well as promoted a new type of gas sensor. The sensor composed of nanomaterials plays a significant role in the development of sensors. Through Chen Ming’s research, it enhanced the gas sensing properties of carbon nanotube films through electrostatic self-assembly [ 1 ]. The recording sensitivity of carbon nanotubes-based gas sensors to nitrogen dioxide at room temperature is 1.97 times higher than that of random equipment of the same dimension, which is due to the use of the specific surface area of a carbon nanotube network, and it dramatically enhances the sensing performance. Ma Defu’s studies demonstrate a visible-light-driven room temperature gas sensor made of novel carbide nanocrystals [ 2 ]. The fluorescence emission of carbide nanocrystals has been attributed to light-driven sensing. The device also exhibits good selectivity and stability. Carbides have high adsorption energy in regards to specific gas molecules and low adsorption energy of other gases, which leads to the detection of certain gases.

This overview reviews the current development of gas sensors and introduces new gas sensors based on various nanomaterials, including their composition, types, principles, characteristics and corresponding applications. Nanotechnology has created great potential for manufacturing high sensitivity, low-cost and low power consumption gas sensors. It mainly introduces gas sensors based on various dimension nanomaterials. In each part, it has the methods we use, the characteristics of various categories and the contribution of each study. Herein, we will discuss how to solve the existing problems and combine their elements and applications to compare the main advantages and disadvantages of gas sensors with various dimensions of nanomaterials. Finally, we give a brief summary on nanomaterials with different dimensions in Table 1 and summarize the development direction of gas sensors based on various dimensions of nanomaterials.

A brief summary of nanomaterials with different dimensions.

2. Gas Sensors Based on Zero Dimensional Nanomaterials

2.1. gas sensors based on carbon dots.

Carbon dots have excellent optical properties, good water solubility, low toxicity, environmental friendliness, are a comprehensive source of raw materials and are low-cost with good biocompatibility [ 3 ]. As one of the zero-dimensional carbonaceous nanomaterials, carbon dots have many peculiar properties such as quantum size, abundant edges, functional groups, high conductivity and so on in physical chemistry, playing an essential role in the development of the nano-field, which is beneficial to the improvement of gas sensing performance, making it the perfect material for a gas sensor.

Jing Hu synthesized reduced graphene–oxide–carbon dots (rGO-CDs) hybrid materials via green one-pot method to situ generate ultra-small-sized surfaces on their surfaces while reducing GO [ 4 ]. The introduction of CDs significantly improves the gas sensing performance of rGO. Composite structures can detect extremely low NO 2 concentrations at room temperature. Prepared rGO–CDs exhibited high sensitivity and good selectivity for NO 2 at room temperature upon exposure. It attributed the improvement of rGO–CDs gas sensing performance to the increase of surface hole density rGO surface, which has few defects regarding residual nitrogen due to the introduction of CDs and the formation of an all-carbon nano heterojunction, which itself significantly promotes charge transfer and exhibits high sensitivity, high stability and high repeatability of an NO 2 gas sensor based on nanomaterials.

This fabrication method forms heterojunctions and a small amount of nitrogen doping in full-carbon nanoscale rGO–CDs, which effectively promotes charge transfer and perfectly demonstrates its good gas sensing performance. In observing the sensing performance of the sensor in the detection rGO-CDs, the sensor has the best performance. It exposed the sensor to air, and the adsorbed oxygen molecules captured electrons from the semiconductor, thereafter obtaining the chemical adsorbed oxygen species. This process resulted in the formation of a depletion layer on the rGO–CDs surface. There are grain boundaries at the same time in many active sites in rGO–CDs and the composite contact gas with NO 2 , and it used the whole carbon nanoscale for the selectivity of NO 2 heterojunction molecules. The nano-heterostructures and a small amount of n doping in carbon dots significantly promote the charge transfer in the depletion layer of nanomaterials. Because NO 2 has lone pair electrons and the interface electron exchange and gas will produce a very intense interaction, the sensor resistance changes dramatically. All of these factors affect the electrical characteristics of the system and significantly improve the sensing performance of the sensor.

Cheng Ming studies gas sensors based on carbon dots. He used simple environmentally friendly hydrothermal methods in the In 2 O 3 nanosphere to change the situation of a delamination situation to improve gas sensing performance. He also used a simple one-step hydrothermal method combined with subsequent annealing processes to prepare uniform and hierarchical In 2 O 3 /carbon-like nanospheres. As validation, it fabricated gas sensors based on In 2 O 3 /carbon dots and investigated their gas sensing properties.

This method makes use of the excellent properties of In 2 O 3 to make gas sensors. When exposed to the air, oxygen molecules will be adsorbed on the surface of In 2 O 3 . These adsorbed oxygen molecules will be ionized by trapping electrons in the In 2 O 3 conduction band to form chemically adsorbed oxygen species. The electron depletion layer will form indium oxide near the surface, which will reduce the electron concentration and increase the resistance [ 5 ]. When exposed to oxidized gases, the construction of nitrogen dioxide molecules that capture electrons from In 2 O 3 to NO 2 - increases resistance after combining with the carbon dots, the successful electron transfer, the formation of the heterostructure of In 2 O 3 and the carbon dots. The shielding effect is due to the introduction of carbon dots and the increased surface adsorption oxygen of the introduction of carbon dots. Carbon dots have several purposes, such as an active surface effect, and they show excellent sensing performance for NO 2 and other gases.

Compared to traditional gas sensors, In 2 O 3 /carbon point gas sensors have apparent advantages. They form heterojunctions at the interface between the In 2 O 3 and the carbon dots; electrons flow from the In 2 O 3 to the carbon dots until the electrical properties are equal; the electron depletion layer widens as the band bends, eventually leading to an increase in resistance. The introduction of carbon dots will produce a shielding effect to reduce the effective nuclear charge. Therefore, the released electrons will be absorbed by nitrogen dioxide molecules, further improving the sensing performance [ 6 ]. The percentage of surface adsorption oxygen increases after the introduction of carbon dots. Since the surface adsorption oxygen has high activity, the increase of surface adsorption oxygen percentage plays a vital role in improving the sensing ability. The rich crystal structure can provide more free electron adsorbed oxygen for atoms to react with NO 2 gas, promoting the sensing performance. The surface of carbon dots has ultra-high stable chemical activity, which is beneficial to the adsorption of NO 2 gas and oxygen so that the reaction can accelerate gas sensing. Because of its unique structure and characteristics, the gas sensor can significantly improve sensing performance.

Ziyang Yu studied the synthesis of ZnO and carbon dots (CDs) via the hydrothermal process [ 7 ]. ZnO/CDs composites were prepared by doping the CDs into the ZnO via the grinding method. X surface area of zinc oxide adsorbed gas can be provided via optical sheet diffraction and scanning electron microscope analysis. The ZnO/CDs composite has a high gas sensitivity response. The gas sensitivity test of the ZnO/CDs composite shows that the sensor has a high NO response. The reaction rate of ZnO/CDs composites to NO is much higher than that of traditional methods, and the active functional groups provided by CDs have a significant effect on the NO.

The most significant difference is that ZnO/CDs composites have enhanced gas response, and the doping CDs have an essential effect on NO. The spontaneous formation of free radicals is a distinctive feature of NO gases. The study on carbon dots introduces the surface of carbon dots with active functional groups, capturing free electrons in the ZnO conduction band in ZnO/CDs composites. When the concentration of the carrier decreases, the conductivity of the material decreases either. The measured resistance value increases, which shows that the gas sensing response of the ZnO/CDs composite is improved and enhanced.

The presence of carbon dots transforms the gas adsorption reaction into the solid-phase contact reaction in the composite, and the electron transfer in the solid-phase contact reaction is more likely to occur. Materials with a porous micromorphology have a large surface area; the larger surface of the material can absorb more oxygen molecules and test the target gas molecules, and more surface contact will occur at this time, resulting in better gas sensing reaction. The microsphere morphology of sheet assemblies with a large specific surface area in ZnO/CDs composites provides more contact with no gases [ 8 ]. The numerous active functional groups doped with CDs provide more non-gas-sensing reaction sites, so this method can increase the gas sensitivity of the material and improve the efficiency of the gas sensor.

2.2. Gas Sensors Based on Nanoclusters

In recent years, nanoclusters have become a new material in the field of nano-research. More and more researchers have paid attention to them, including, specifically, gold nanoclusters, as they are considered the most typical representative of metal nanoclusters, having more engagement. Gold nanoclusters are molecular level aggregates with fluorescence properties prepared from organic molecules as templates. Their size is similar to a fermi wavelength and can produce specific energy level separation. Therefore, it emitted fluorescence under excitation at a specific wavelength. Compared to traditional fluorescent materials, such as organic fluorescent dyes and nanoparticles, gold nanoclusters have become excellent materials for gas sensors because of their simple preparation methods and unique physicochemical properties. Nanoclusters have developed well in the research and manufacture of gas sensors because of their rich characteristics, such as light stability, excellent biocompatibility, light induced flourescence and outstanding sensing performance.

Hossain Khan studied a highly sensitive and selective nitrogen dioxide detection method [ 9 ], which itself functionalized Gallium Nitride (GaN) submicron wires with titanium dioxide (TiO 2 ). The nanoclusters fabricated dual-terminal gas/TiO 2 sensor devices using a top-down approach. Gas sensing makes it possible for the sensor to work at room temperature. After the study, it was found that the sensor had high selectivity to NO 2 and can resist other interfering substances. The sensor device had good long-term performance stability at room temperature and humidity, and is relatively stable and reliable in various climates.

This study uses metal oxide nanocluster functionalized GaN sensors to realize the sensing of NO 2 molecules. Under UV irradiation, metal oxide nanocluster photolysis water absorption and water in the GaN create oxygen-producing surface defect active sites and electron-hole pair frameworks; target analytes undergo chemisorption at these active sites; adsorption molecules dynamically capture and de-capture charge carriers at these active sites for GaN potential modifications of the main chains, leading to modulation of sensor currents, proportional to analyte concentrations [ 10 ]. Oxygen molecules are chemisorbed on Ti 3+ vacancies on the TiO 2 surface to obtain negative charges. Meanwhile, molecular adsorption or dissociation adsorption occurs on the surface of water molecules, and TiO 2 cluster surfaces produce oh substances at the Ti 3+ defect sites, which also have many advantages as a sensor. When the energy is higher than the bandgap energy of GaN and TiO 2 , it activates electron-hole pairs in GaN and TiO 2 clusters under UV excitation [ 11 ]. The carrier lifetime increases in the GaN submicron line due to the rise of photocurrent increases due to the bending of the surface energy band photogenic pores to the GaN surface. Chemisorbed oxygen and water are received TiO 2 molecules on nanoclusters and desorbed [ 12 ]. It adsorbs Nitrogen dioxide directly on these newly generated sites due to the high affinity of molecules. Some NO 2 molecules interact with and are adsorbed on the surface chemically adsorbed oxygen. TiO 2 nanoclusters and NO 2 molecules increase the depletion region width inside the GaN, thus reducing the sensitivity current of the sensor. The desorption of light-induced oxygen and subsequent charge transfer TiO 2 nanoclusters and NO 2 molecules to regulate the depletion region width within the GaN, thus contributing to high-performance NO 2 gas sensing.

Mingyuan Wang studied a gas nanosensor system combining silver nanoclusters with phosphorene [ 13 ]. The Ag N nanoclusters (1 ≤ N ≤ 13) can effectively reduce the degradation of phosphorene and hypophosphorous in the catalyst and exhibit various structures. Exposure to other active adsorbents can play a good adsorption role, which significantly improves the selectivity and sensitivity of the system to adsorbed molecules. Because of the participation of valence electrons, the modification of silver atoms from electron orbit can improve the sensitivity of phosphorene. It can also regulate the charge distribution between atoms to adsorb molecules and phosphorene. When the gas flows, the work function of the molecules adsorbed on Ag 1 phosphorene changes significantly, the adsorption amount of NO 2 molecules increases significantly, and NO 2 adsorption requires higher bias voltage than that of Ag 1 phosphorene. Then, the sensing of NO 2 gas is achieved.

This study proposes a silver-trimmed phosphorene composite system for gas sensing, which can prevent silver aggregation nanoclusters and reduce the degradation and passivation of phosphorene by metals through stronger interactions. It improved the selectivity and sensitivity by adjusting the adsorption energy and temperature [ 14 ]. In this study, the reagent has good selectivity and stability. The sensitivity of four molecules to phosphorene can significantly improve the modification of silver nanoclusters via surface modification. Single Ag decoration can improve the adsorption performance of NO 2 molecules, enhance the sensitivity and selectivity of NO 2 molecules and make it an ideal material for gas sensors.

The excellence of this experiment is that phosphorene is a suitable scattering substrate. Silver nanoclusters are efficiently sensed by increasing the binding of silver phosphorene and weakening the silver–silver bond. Single Ag and Ag 1 phosphorene show that Ag atoms cannot only increase the adsorption energy but also increase the energy difference, which means that the phosphorene modified by single silver can improve the sensitivity of the four gas molecules [ 15 ]. NO 2 adsorption requires higher bias voltage than single silver-modified phosphorene. With the increase of the number of Ag nanoclusters, the stability of Ag N nanoclusters to the adsorption energy of gas molecules is enhanced, which provides a variety of ways for the selective adsorption of gas molecules. Silver decoration can create new synergistic effects, improve efficiency by adjusting adsorption strength and temperature, and then enhance the sensitivity and selection characteristics of the phosphorene surface as a gas sensing element.

In YoungMin Byoun’s research, they synthesized heterostructured nanomaterials composed of p-type TeO 2 NWs and discrete n-type ZnO nanoclusters to detect NO 2 gas molecules [ 16 ]. These nanomaterials are synthesized via thermal evaporation and atomic layer deposition, and then the ability of NO 2 in terms of operating temperature, NO 2 response and selectivity was systematically investigated [ 17 ]. By forming discrete n–ZnO nanocrystals, it enhanced the reaction of the p-TeO 2 nanocrystalline sensor to NO 2 significantly. The synthesized sensors also show good NO 2 selectivity compared with SO 2 , C 2 H 5 OH and other interfering gases, forming discrete n–ZnO nanocrystals to improve the sensing ability of gas sensors to NO 2 significantly.

This study demonstrates an excellent reaction and results. ZnO-TeO 2 heterostructures exhibit good NO 2 gas sensing performance by electron sensitization. The heterojunction generated by n–ZnO functionalization can give the p–TeO 2 nanowires better resistance; besides, heterojunction nanowires are beneficial to the detection of oxidizing gases, and when p–TeO 2 contact n–ZnO, the flow of electrons from n-ZnO to p–TeO 2 —transferred to the n–ZnO to balance the Fermi level—results in a barrier with band bending [ 18 ]. As a result, the relative change of hal volume caused by adsorption and desorption of oxidant is more significant than that of reductive gas. Compared to SO 2 molecules, NO 2 molecules are more readily adsorbed on the surface ZnO–TeO 2 heterostructure nanocrystals. As a result, the response to the NO 2 is significantly enhanced.

The advantage of this study is the synthesis of heterostructures p–TeO 2 , the continuous functionalization of n–ZnO nanocrystals using thermal evaporation and ALD processes. It characterized and tested the synthetic products and systematically studied the SEM, XPS and NO 2 of the models. Fabricated sensors show significantly improved NO 2 sensing capabilities far better than the original sensors. Specifically, n–ZnO nanocrystals have a positive influence on the NO 2 response. The n–ZnO nanocrystals are functionalized on the surface of the p–TeO 2 nanocrystals, thus demonstrating good sensing performance for the gas.

2.3. Gas Sensors Based on Metal Nanoparticles

With a deepening of the research of nanomaterials, the huge application potential of gold nanoparticles in the field of gas detection technology has been widely recognized. Nano gas probes and their corresponding detection technology have been highly valued. In recent years, hybrid systems of gas molecules and spherical gold nanoparticles have been widely used in various biological analyses and have achieved encouraging results. Due to the characteristics of easy preparation, easy biochemical modification, high density and high dielectric constant, it used gold nanoparticles to prepare gas sensors to detect specific gases.

Sh.Nasresfahani investigated the effects of gold nanoparticles on the performance of CO gas sensing sensors [ 19 ]. It comprehensively studied room temperature properties of polyaniline and prepared Au/PAni nanocomposites. Also, it modified the fiber surface due to electrostatic interaction and hydrogen bonding PAni via emission scanning electron microscopy and x-ray spectroscopy analysis. Then, the study analyzed the gas sensitivity of each sensor to various carbon monoxide gases in a concise range. Experiments show that the Au/PAni sensor has high response and low noise, a very short response time, a wide dynamic range and good stability. The catalytic performance of gold nanoparticles determines their selectivity and the good sensing ability of the sensor.

The difference between this study and the traditional method is that it enhanced the sensitivity of p semiconductor PAni to CO gas after introducing au nanoparticles. The positive direction on the carbon atom transfers to the nitrogen on the amine, which increases the amount of the positive charge, so the conductivity of polyaniline increases. When it introduced gold nanoparticles into polyaniline, the Au–NPs can interact with CO molecules and transfer positive charges to polyaniline, which significantly improves the sensitivity of the sensor [ 20 ]. It prepared Au/PAni nano composites by ultrasonic mixing under appropriate conditions. The physical mixing of the two components resulted in negatively charged metal nanoparticles deposited on the positively charged polyaniline surface. Since the high surface energy of gold nanoparticles creates adsorption sites for CO gas molecules, the prepared sensors exhibit good gas sensing properties for various concentrations CO at room temperature.

Do Wan Kim proposed a highly sensitive and rapidly responsive nitrogen dioxide gas sensor based on gold nanoparticles modified zinc oxide nanowires. On the surface of zinc oxide nanowires, it modified gold nanoparticles on its surface by electrostatic force. The models without the aptes layers exhibit high NO 2 gas sensitivity due to the local surface plasmon resonance (LSPR), and, incredibly, the increase of the NO 2 gas response and response time was three-fold. Compared to the unmodified ZnO nanowires, the time was reduced by 80%. The presence of aptes layer improves the attachment of gold nanoparticles, and the LSPR effect can significantly improve the efficiency of gas sensors.

Figure 1 illustrates the machine-made strengthened NO 2 gas response of Au–ZnO and Au–ZnO/APTES through diagrams, especially the absorption and suction mechanisms in the dark and under green clearing luminary. We discussed two typical adsorption avenues here: the immediate chemisorption of NO 2 gas onto the ZnO surface by catching the electrons of the ZnO surface itself and the removement of the NO ions from the Au NPs where NO 2 gas catches the electrons of the Au NPs. The suction of the NO ions should only emerge on the ZnO surface. As shown in Figure 1 a, the Au NPs adherence should enhance the NO 2 gas adsorption under green lighting by engendering plasmon-mediated hot electrons from the Au NPs. In detail, both the afflux of hot electrons and the light stimulates electrons from the defect levels broaden the conducting channel of the ZnO NW under green light. Then, the NO 2 gas adsorption on the ZnO surface is extended by the increasing number of electrons, extending the depletion region by capturing the electrons. Then, the electric channel of the ZnO NW becomes narrower, as revealed by the red hollow cylinders in Figure 1 a. As a result, Au–ZnO achieved the maximum improvement ratio and NO 2 gas response. Even though the suction of the adsorbed NO 2 and O 2 ions was also enhanced by the generation of holes in the ZnO NW under green lighting, the hotelectrons-associated gas adsorption procedure appeared to be improved.

Schematic mechanisms for the enhanced NO 2 gas response of the Au nanoparticles-decorated ZnO nanowires, ( a ) without (Au–ZnO) and ( b ) with a (3-aminopropyl) triethoxysilane layer (Au–ZnO/APTES), in the dark ( left ) and under green illumination ( right ). The curved red arrows indicate the NO 2 gas adsorption and desorption processes, whose acceleration and diminishment are represented by the arrow thickness. The solid and dashed lines denote, respectively, the intrinsic conduction (EC) and valence (EV) bands and the Fermi (EF) and defect (Ed) levels. Reprinted with permission from Ref. [ 20 ].

On the other side, the APTES layer on the ZnO NW surface exerts an influence in the NO 2 gas absorption of Au–ZnO/APTES. The APTES layer hindered the NO 2 gas adsorption onto the ZnO NW, as certified by the PC decay results revealed in Figure 1 a,b and testified by the comparatively thin arrows of NO 2 in Figure 1 b. In contrast, once the NO 2 gas was adsorbed onto the ZnO NW surface of Au–ZnO/APTES, its suction was comparatively less hindered by the APTES layer compared to the absorption procedure. Au–ZnO/APTES showed a broadened electric channel of the ZnO NW under green lighting due to the afflux of hot electrons and the light stimulates electrons, similar to that of Au–ZnO. However, since the NO 2 gas adsorption on the ZnO NW surface was not abundantly expedited due to the hindering of the APTES layer, the narrowing in the electric channel of the ZnO NW was smaller compared to the Au–ZnO case. This could explain the comparatively small NO 2 gas response of Au–ZnO/APTES under green lighting with respect to Au–ZnO despite the LSPR effect of the Au NPs. Furthermore, for all three samples, both the red and green lighting obviously expedited the NO 2 gas suction procedure more than the adsorption one, except for the green lighting of Au–ZnO, where the LSPR effect was outstanding. Consequently, the NO 2 gas sensing mechanism of the samples could be directly proofed with the unity of the hot electron generation from the Au NPs via LSPR and the gas adsorption reduction by the APTES layer.

In the research of a gas sensor, there is a unique treatment. Plasma mediated enhanced the room temperature NO 2 gas sensing properties of gold, NPS modified ZnO nanowires, and proposed potential mechanisms for improved LSPR effects. The charge transfer resulting from the LSPR effect in Au–ZnO was characterized via light-irradiated (red and green, 650 and 532 nm, respectively) KPFM measurements. Compared with pristine ZnO nanowires, they have higher gas sensing performance, uniquely faster response time. Gas-sensitive properties of this hot electron increase sharply because it captured the hot electron by NO 2 gas easily and accelerates its chemisorption on the surface of zinc oxide [ 21 ]. Stimulated by hot electrons, it replaced the adsorption process of NO 2 gas by light-excited holes to understand the absorption process [ 22 ]. The LSPR effect of hot electrons can improve the response to NO 2 gases and significantly accelerate the response time of ZnO films. The performance of gas sensors can be significantly improved by using the LSPR effect.

Pu Li proposed in this study to fabricate microstructured gold nanoparticles functionalized gas sensors that are assembled and deposited between two electrodes. In response to volatile organic compounds, it determined the change of conductivity by interparticle properties such as a dielectric constant. The micro sensor shows the reaction of seven target analytes to o-xylene [ 23 ]. This micro-sensor exhibits a larger response to o-xylene than conventional sensors, improving sensitivity and shortening the response time to other volatile organic compounds because the larger surface volume results in better sensing performance than surface roughness and device miniaturization [ 24 ]. The gas sensor, composed of gold nanoparticles, produces an obvious reaction in a short reaction time.

An SEM image shows the surface morphology film of the sensor, which indicates that the microsensor has large surface roughness and surface volume ratio. The higher response is due to the enhanced surface effect, and the larger surface volume ratio can shorten the precipitation time of the gas. The miniaturization of gas sensors brings higher response speed and shorter response time. We compared the response time of various micro-sensors. For gas sensors based on gold nanoparticles, the response time of the VOC test is much shorter than that of other volatile gases. Compared to the laser-made micro-sensor by writing technology, the micro-sensor shows the excellent response to gas.

Electron transport between particles in this study is a unique method and there is no chemical reaction between nanoparticles and gas molecules. Nanoparticles are exposed to analytes, and the VOCs of the adsorption sensor surface can cause changes in physical parameters [ 25 ]. When the polar gas molecules diffuse in the air, the sensor, composed of gold nanoparticles and their binding nanoparticles, expands the distance particles between the particles. The diffusion analyte changes the permittivity constant and the interparticle distance. Using laser writing techniques, gold nanoparticles were successfully self-assembled at two electrodes. Gas sensors exhibit the selectivity of gold nanoparticles in 7 analytes [ 26 ]. Due to the excellent performance of the rough surface and high response and short response with the miniaturization of the device, the gas sensor, based on gold nanoparticles, shows a very high response-ability to gas matter.

Ahmad I. Ayesh investigated PbS nanocrystals, and this substance has recently shown room temperature sensing capability for specific gases (CH 4 ) [ 27 ]. Gold is another common noble metal used as an additive to improve device performance. The incorporation of gold nanoparticles (NPs) can improve methane sensing properties. PbS-NCs shows that adding appropriate amount of Au–NPs can improve PbS-NCs methane sensing characteristics, and studied and analyzed the conductivity, sensor response and sensor speed.

In this study, it studied the effect of gold nanoparticles on PbS electrical properties through various properties. Introducing Au–NPs into the PbS-NCs is feasible to reduce their electrical conductivity. The reaction of the Au–NPs sensor modified on the PbS-NCs surface improves its speed. The main reason is that Au–NPs can produce more oxygen adsorbed on the PbS–ncs surface, and methane molecules find that more adsorbed oxygen will affect the PbS–ncs surface [ 28 ]. In similar cases, for the same concentration of methane, it involved more oxygen ions by methane. This not only makes the sensor more sensitive but also more efficient than in the traditional way. The enhancement of gold to oxygen adsorption can improve the properties of the sensor by competing methane molecules and adsorbed oxygen interaction between gold and gold nuclei. With low methane concentrations, when we added PbS-NCs as more gold nuclear power sources changes, PbS–NCs occurred, and it adsorbed more oxygen by methane molecules and more essential conduction. At high methane concentration, there will be competition between gold nuclear power sources and interaction between CH 4 molecules and adsorbed oxygen, which will produce a better gas response. The effect of various gold content on PbS–NCs decoration affect NPs conductivity and the effect of methane sensing significantly improves its performance. The appropriate amount of gold nanoparticles enhanced the efficiency of the reaction and forms a more efficient gas sensor. (This section closely follows the topic to discuss. The knowledge of nano aspects is well used to analyze and solve the sensor problems. In this part, by reading a large number of data about gas sensors composed of nano materials, the experimental processes of different methods are analyzed in detail, and the analyzed data are compared. The advantages and disadvantages of different kinds of nano sensors are obtained, which shows the diversity of nano sensors.)

3. Gas Sensor Based on One Dimensional Nanomaterials

3.1. gas sensors based on nanowire.

The continuous progress of global industrialization not only improves production and living standards but also destroys the environment in varying degrees [ 29 ]. With the increasing diversity and complexity of harmful gas components in the background in recent years, human health and production safety are in crisis, and people’s awareness of self-protection is improved. Therefore, it is necessary to realize the real-time monitoring of toxic and harmful gases in the environment. Because of its advantages of high sensitivity, easy preparation and low cost, nanowire materials have developed well and play an essential role in the market, and the device performance has been gradually improved nanowire material as the carrier. By regulating its structure and morphology and exploring the synergistic recombination with other semiconductor metal oxides, we try to construct the correlation between material characteristics, gas sensing performance and sensing mechanism, and then improve the gas sensing performance of the sensor composed by it, which lays a foundation for further development in the future.

Zhicheng Cai synthesises SnO 2 nanowires modified by Pd nanoparticles to prepare highly selective and sensitive nanowire hydrogen sensors [ 30 ]. It prepared the SnO 2 nanowires by steam–liquid–solid process and modified the Pd nanoparticles by UV with a PdCl 2 solution to improve the hydrogen sensing performance of the SnO 2 nanowires. Pd nanoparticle-modified SnO 2 nanowires have good electrochemical performance, and various hydrogen-sensitive responses increase with an increasing number of Pd nanoparticles. Furthermore, the selectivity of this nanowire-based sensor also increases the nanoparticle with increasing Pd. SnO 2 and the sensing response of nanowires to several gases is similar, as they enhanced the hydrogen sensing response to other gases after various palladium nanoparticle modifications significantly.

Another special feature of this research is that when SnO 2 nanowires are exposed to the air, the oxygen in the air is adsorbed on the surface of the nanowires due to the attraction of static electricity. It converted the adsorbed oxygen into oxygen ions to adsorb electrons on the surface of SnO 2 nanowires, SnO 2 the surface depletion layer of nanowires expands and the resistance increases. When it exposed such nanowires to hydrogen, it adsorbed hydrogen on the surface of SnO 2 nanowires. Hydrogen reacts with oxygen ions adsorbed on the SnO 2 surface, and hydrogen is converted into H 2 O gas. Through this reaction, electrons absorbed by oxygen ions return to the SnO 2 nanowires, SnO 2 the carrier concentration, surface width and resistance of the nanowires return to the initial state. In this case, the palladium adsorbed nanoparticles, after the reaction with palladium nanoparticles, the electronic band structure changed and the initial dl was formed on the surface of SnO 2 nanowires when it exposed Pd nanoparticle-modified SnO 2 nanowires to air, it adsorbed oxygen by electrons of Pd nanoparticles. SnO 2 the surface of nanowires, it significantly reduced the resistance of such nanowires in the hydrogen environment due to the SnO 2 use of electrons as electrical carriers. After modifying Pd nanoparticles, the behavior of this nanowire in exposure to air and hydrogen and the change of gas sensing characteristics were more pronounced.

Tzu-Feng Weng used the vapor–liquid–solid growth method to grow high-density β-Ga 2 O 3 single crystal nanowires on silicon substrates, and studied the room temperature CO gas sensor of pure nanowires and gold-modified nanowires using multi-network arrays and single nanowire devices [ 31 ]. It studied the synthesized nanowires by field emission scanning electron microscopy. It fabricated single nanowire gas sensors by focusing ion beam technique. A single nanowire RT-CO gas sensing sensor using the proposed Au changed the β-Ga 2 O 3 nanowire to achieve remarkable sensitivity to CO gas at room temperature. It also compared the sensing characteristics β-Ga 2 O 3 RT-CO gas multi-network Au modified nanowires and single Au modified nanowires.

This study, due to the superior and stable RT gas sensing properties of gold, analyzed the effect of various gas concentrations on the performance of β–Ga 2 O 3 nanowire devices after modification. Various gas sensors have various measurement results in CO gas concentration. With the decrease of gas concentration, the response time and recovery time gradually decrease and increase. The activation energy of oxygen atoms pre-absorbed on the surface of gold nanoparticles adsorbed upon CO molecules decrease [ 32 ]. The length of response and recovery time depends on the availability of a large amount of oxygen trapped on the surface of the sample. If the number of oxygen vacancies increases, the pressure on the surface of the number of trapped oxygen molecules increases, which in turn enhances the efficiency of the sensor. It operated the CO-gas sensor by adsorption, the resistance decreases when the reducing agent reacts on the surface of the material. After it chemisorbed and absorbed the oxygen in the semiconductor by the reduced gas, the result is a free electron in the form of increased conductivity. The gas sensing structure diagram is shown in Figure 2 . Small fragments of the oxygen ion monolayer were absorded and formed additional deoxyribonucleic acids near the ion surface [ 33 ]. This is also the reason for the excellent gas sensing performance of Au modified β-Ga 2 O 3 .

An architecture diagram of a CO gas sensing measuring unit. Reprinted with permission from Ref. [ 31 ].

J.Y. Lin studied an SnO 2 nanowire hall-effect gas sensor for hydrogen detection [ 34 ]. It prepared SnO 2 nanowires on stainless steel mesh by horizontal electric furnace, and it analyzed the crystal structure, morphology and electron binding energy of SnO 2 nanowires by XRD, XPS. Gas response to H 2 at various operating temperatures and H 2 concentrations. It investigated a response mechanism of a SnO 2 -based hall-effect gas sensor. Hall effect gas sensors based on SnO 2 nanowires have super-high response and efficiency in preparing low-cost and high-performance gas sensors.

Compared to the experimental results of pure SnO 2 gas sensors, the response characteristics of hall-effect sensors are better. SnO 2 nanorods evaporation was synthesized via thermal method, which has a high response to H 2 . The sensing mechanism of target gas and hall effect principles with the surface reaction of hydrogen and oxygen was adsorbed on metal surface SnO 2 nanowires. It absorbed the electrons by atoms to adsorb oxygen molecules from the conduction band of electrons to form SnO 2 nanowires and oxygen ions on the surface, which leads to the decrease of electron density on the surface of SnO 2 nanowires [ 35 ]. The carrier concentration increased with time, and it exposed the gas sensor to hydrogen. With the growth of hydrogen concentration, the carrier concentration increased further. When it introduced hydrogen, hydrogen reacted with adsorbed oxygen. The absolute value of the hall coefficient increased with the increase of H 2 concentration, and the decrease of hall voltage decreased with the increase of H 2 concentration. Good sensing performance was therefore shown in response to a specific gas.